Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Seite/page

21

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

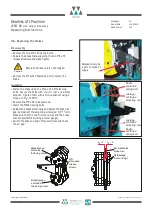

traction sheave types and brake arrangements must be

taken into account in regard to the arrangement of the

return motion device.

Then screw the threaded bolt into an appropriately posi-

tioned threaded hole in the traction sheave using a span-

ner. While releasing the brake magnets, either electrical-

ly or using the brake lever plates, the slide block can be

displaced by turning the corresponding nuts. This turns

the traction sheave.

The bolt can then be moved to a new hole in the traction

sheave, if required.

The lift must be braked when changing the

bolt.

A mechanical return motion device can be fitted at the

operator's own responsibility if the lift needs to be

moved manually in case of a breakdown or if the car is

caught by a safety device. The use of the return motion

device is shown in the drawing.

Bolt the bearing block to a cross-beam at

the recommended spacing. The cross-beam

is firmly connected to the lift machine.

When fitting the device, a switching com-

mand "electrical supply disconnected" must

be activated.

The specific conditions resulting from the different

Danger

Note

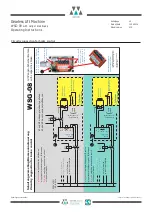

Return motion device

Other recommended values for

the use of the return motion

device:

Angle

a

: ca. 30° to 50°

max. permissible traction force

FZ: 9 kN

traction sheave

X5 X6 X7

ØD

T

B

T

FB

T

WSG-08.1

WSG-08.2

WSG-08.3

4 0 X7

400

60

166

505 382 002

4 S X7

70

176

4 E X7

82

188

4 N X7

90

196

3 S X7

340

70

196

3 N X7

95

221

WSG-08.4

4 T X7

124

284

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......