Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Seite/page

22

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

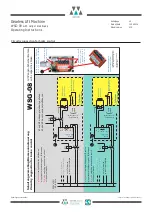

9.5. Replacing the traction sheave

The traction sheave can work loose if it is

not properly installed.

Disassembly

•

Power off the system and safeguard against uninten-

tional reclosing.

•

Secure the car and the counter-weight.

•

Remove the rope slip-off guards and the rope guards, if

provided.

•

Relieve the load on the traction sheave; remove the ropes.

•

Support the traction sheave by means of a hoisting gear.

•

Remove the 12 fastening bolts.

•

for D

T

= 400 mm: Insert the M12x50 bolts into the two

threaded forcing holes and force off the traction sheave.

Danger

Assembly

•

Clean the traction sheave and the rotor flange.

•

For better assembly heat up traction sheave.

•

Slide the traction onto the rotor flange as far as possible.

•

Insert the fastening bolts and tighten diagonally oppo-

site bolts. Use "omnifit 100" or a similar adhesive to

secure the bolts. Tighten them along the bolt hole circle

(M

A

= 115 Nm) with a torque spanner.

•

Replace the ropes and reinstall the rope slip-off guard.

•

for D

T

= 340 mm: Insert a suitable extracor tool into the

two threaded forcing holes M16x25 and remove the

traction sheave.

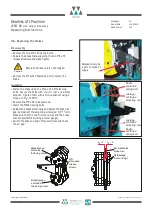

Abdrück-

gewinde M

16

forcing thread

holes M

16

D

T

=

340

mm

Abdrück-

schraube M

30

forcing bolt M

30

Druckscheibe

pressure

disc

Befestigungs-

schrauben M

12

fastening bolts M

12

29

6

m

m

Abdrückschrauben

M

12 x 50

forcing screws

M

12 x 50

D

T

=

400

mm

Befestigungs-

schrauben M

12

fastening bolts M

12

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......