Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Seite/page

24

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

The modification may only be made by a

qualified personnel. Life-threatening situa-

tion in case of misapplication !

To adapt the brakes to special rope guid-

ance, the brake variants "RHS + LHS",

"RHS + top-mounted" or "LHS + top-mount-

ed" are available.

If a subsequent change is required, proceed

as follows:

Removing the brake with flange (1)

•

4 Slacken the 4 Allen screws (2) M10.

•

Release the brake manually using the two M6 x 65 release

screws supplied (see chapter „Replacing the brake“)

•

Remove the screws (2).

•

Force off the pinned (3) flange (4) using a suitable tool.

Note

•

Take off the brake carefully and remove the pins.

Fitting the brake with flange (1)

•

Release the brake manually with the release screws and

place it carefully on the brake disc (5). When fitting the

brake on top, add the 4mm shim (6).

•

Screw in loosely the 4 screws M10x25, on top M10x30

(2).

•

Remove the release screws (causing it to brake) and

tighten the screws (2) using a torque of 48 Nm.

•

Release the brake electrically and adjust the brake gap

(see chapter „Replacing the brake“)

•

Disconnect the brake from the mains (causing it to

brake) and locate the flange (4) on (5) as shown in the

figure using the 2 straight pins (3). When drilling into

(5) use the predrilled holes in (4).

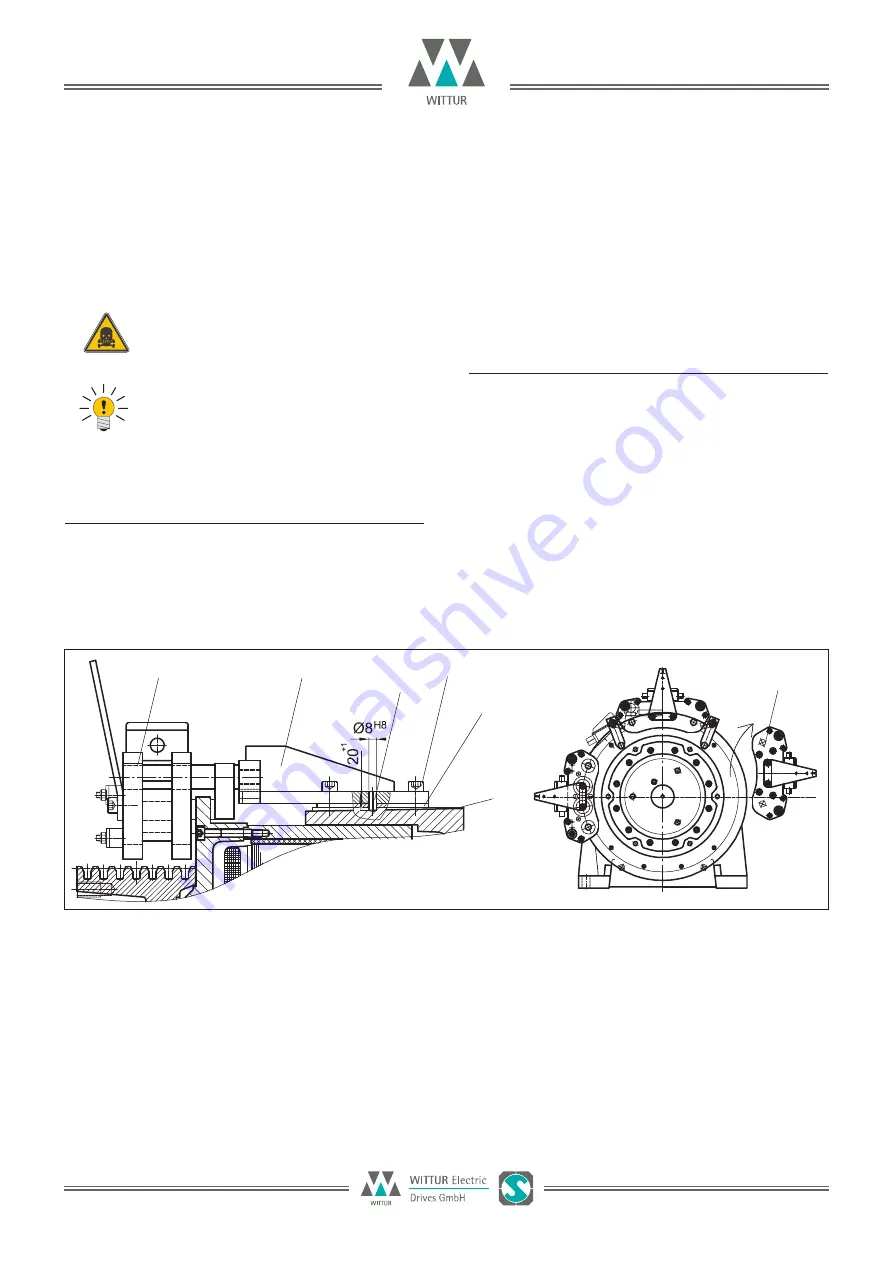

9.7. Modification of brake arrangement WSG-08.1-3

Danger

1

4

3

∅

8x 20

2

6

5

1

only when top

mounted

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......