Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

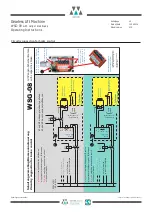

The compact flat-type gearless WSG-08 lift machines are

designed for gearless traction sheave lifts with or with-

out a machine room. They are intended for operation

with a 2:1 or 1:1 suspension and are distinguished by

their high efficiency, extremely low noise and excellent

operating characteristics.

The WSG-08 gearless lift machines are designed solely for

use with electronic frequency converters.

The synchronous motor has been designed for various

rated torques, based on a number of overall widths. It

can also be supplied for several rated speeds, which can

then be further adapted to meet individual customer

requirements.

The brake disc is cast onto the spheroidal cast iron rotor

to which the traction sheave (5) is also connected posi-

tively and by frictional contact. The traction sheave is

optimised for customer-specific dimensions and grooves.

Six threaded holes (6) are provided on the front end

periphery, permitting a mechanical return motion device

to be fitted in case of an emergency.

The rotor with shaft (7) is inserted in the stator frame

and supported in a robust self-aligning roller bearing (8)

in the main bearing head and, at the other end, in a sup-

porting ball bearing (9) or, if the traction sheave diame-

ter is 340 mm, in a cylindrical roller bearing. The bearing

is preloaded axially using an ondular washer (10) for

noise reduction. The bearings are sealed on both

sides and life-lubricated. The main bearing has a provi-

sion for relubrication.

The drive-specific measuring system (11) is located within

the centre of the machine behind the ball bearing. It is

connected to the power supply by a signal plug connec-

tor (12). Within certain limits, depending on the motor

dimensions, different measuring systems can be installed.

The electrical connection of the motor is made in the

terminal box (13) where the temperature monitoring

device is also connected.

The EC type-examined brake system comprises two or

three external caliper disk brakes (14), which are con-

nected to the supply voltage via separate brake control

devices. The devices are located in the respective termi-

nal boxes (15), which also accommodate the terminals

for the monitoring contacts. Each brake can thus be

released individually. The brakes can also be released

manually, if required, by fitting lever eye bolts or a Bow-

den cable to the lever plates (16).

The brakes are designed such that in the case of failure

of one brake the remaining brakes are able to decelerate

a car carrying a full payload.

The two rope slip-off guards (18, 19) can also be fitted at

locations 20 and 21 if required.

We would like to refer to the relevant patents held by

KONE Corporation for lifts without machine room.

Seite/page

6

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

2. Product description

3. Nameplate

Type code of

lift machine

Rated voltage

Rated speed

Rated torque

Serial no.

Rated frequency

The nameplate of the lift machine is on the motor frame.

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......