Maintenance and repair

INTORQ | BA 14.0177 | 04/2016

24

7

Maintenance and repair

7.1

Inspection intervals

The spring-applied brake must be checked during the prescribed inspections of the drive system in which it

is installed.

The service life of the brake before replacement does not only depend on the number of emergency brak-

ings. The wear of the brake friction linings varies depending on the operating conditions. The friction work

possible before replacement decreases with every braking when the switching energy increases.

7.2

Inspections

7.2.1

Braking torque / delay check.

1. Switch on the power supply for the brake.

2. Use a feeler gauge to check the air gap "s

L

" between the brake disc and friction lining. It should not ex-

ceed "S

Lmax.

", according to the table (

3. Switch off the power supply.

7.3

Maintenance

The brake does not require any maintenance when it is being used as a holding brake. The brake is replaced

in the reverse order of the assembly (

1. Switch on the current for the brake

or

screw in the transport screws (M6x65 with Ø23 washer).

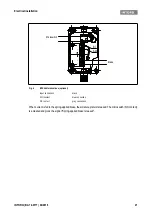

2. Loosen the fixing screws at the guide sleeves (Figure 1).

3. Remove the brake radially from the brake disc.

4. Switch off the power supply and disconnect the connecting cables.

DANGER

Make sure that you remove all loads from the drive. Otherwise, there is a risk of an accident.

The motor must

not

be running when checking the spring-applied brake.

DANGER

Make sure that you remove all loads from the drive. Otherwise, there is a risk of an accident.

The motor must

not

be running when work is being carried out on the spring-applied brake.

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......