4. Scope of supply

Gearless Lift Machine

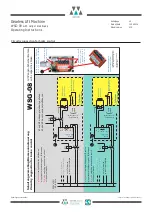

WSG-08

with caliper disk brake

Operating Instructions

•

Lift machine WSG-08 according to order specification

•

Operating instructions

•

Delivery note

Options:

•

Release lever set with remotely controlled bowden cable

•

Return motion device

•

Connecting cable for measuring system

•

Cable set for motor and brake

•

UL-CSA approved

Seite/page

8

Datum/date

12.08.2016

Stand/version

0.18

Änderungen vorbehalten! Subject to changes without notice!

5. Transport and storage

The lift machines leave the factory in perfect condition

after being tested.

Make a visual check for any external damage immediate-

ly upon their arrival on site. If any damage incurred in

transit is found, make a notice of claim in the presence

of the carrier. If necessary, do not put these machines

into operation.

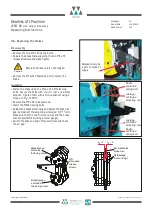

Transport

Observe the relevant safety regulations and

take the centre of gravity into account

when handling the lift machines.

The eyebolts are designed for the specified machine

weight, i.e. it is not permitted to suspend additional

loads.

Storage

Store the motors only in closed, dry, dust-free, well-ven-

tilated and vibration-free rooms (storage temperature:

-20°C to 60°C). Do not store lift machines in the open air.

Bright parts are not sufficiently preserved to withstand

extended periods of exposure.

Avoid excessive storage periods (recommendation: max.

one year).

After prolonged storage (>3 months), rotate the motor in

both directions at a low speed (< 20 min

-1

) to allow the

grease to distribute evenly in the bearings.

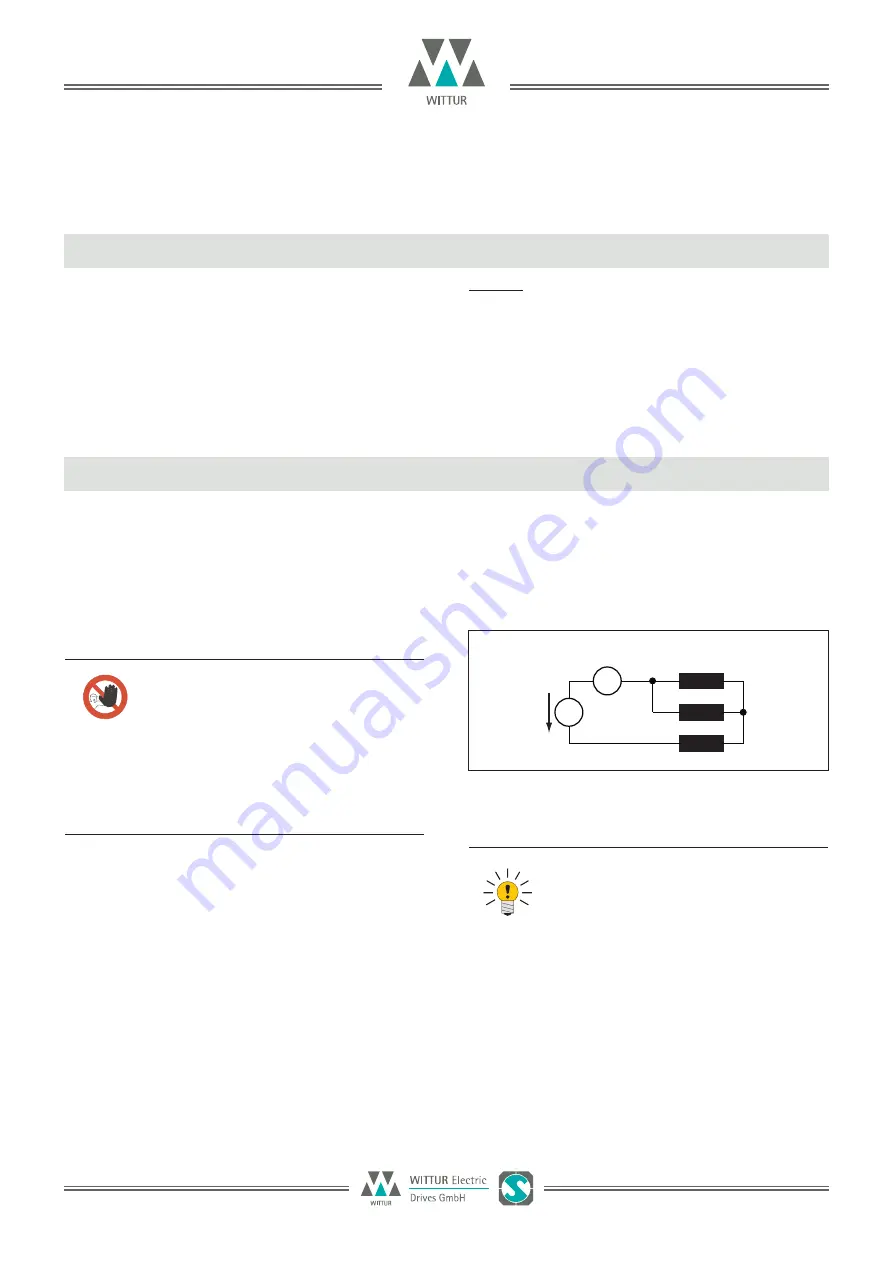

Measure the insulation resistance before initial operation

of the machine. If the value has dropped below < 1 k

W

per volt of rated voltage, the winding needs to be dried

(insulation meter voltage: 1,000 V DC).

Unpacking

Dispose of the packaging material in an

environmentally friendly manner or reuse

it.

Any special transport aids or shipping

braces are left with the customer.

Warning

Note

This can be done, for instance, with heated air, in a dry-

ing oven, or by applying a d.c. voltage to the motor con-

nections.

Make sure that the voltage selected does not exceed the

values shown in the figure "Drying the winding". Let the

temperature rise to about 70 – 80°C and maintain it for

several hours.

u

v

w

A

I

≈

45% I

N

-

U

Drying the winding

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......