M

3~

U1

V1 W1

PE

T1

T3

T2

T4

S1

S3

S2

S4

L

N

υ

υ

υ

υ

υ

υ

υ

M

M

16

C

M20x1.5

M75x1.5

U1

V1

W1

M20x1.5

Gearless Lift Machine

WSG/WGG-29

Operating Instructions

Code

GM.8.002662.EN

Date

04.02.2019

Version

0.19

Page

10

Subject to changes without notice ! Subject to changes without notice !

EN

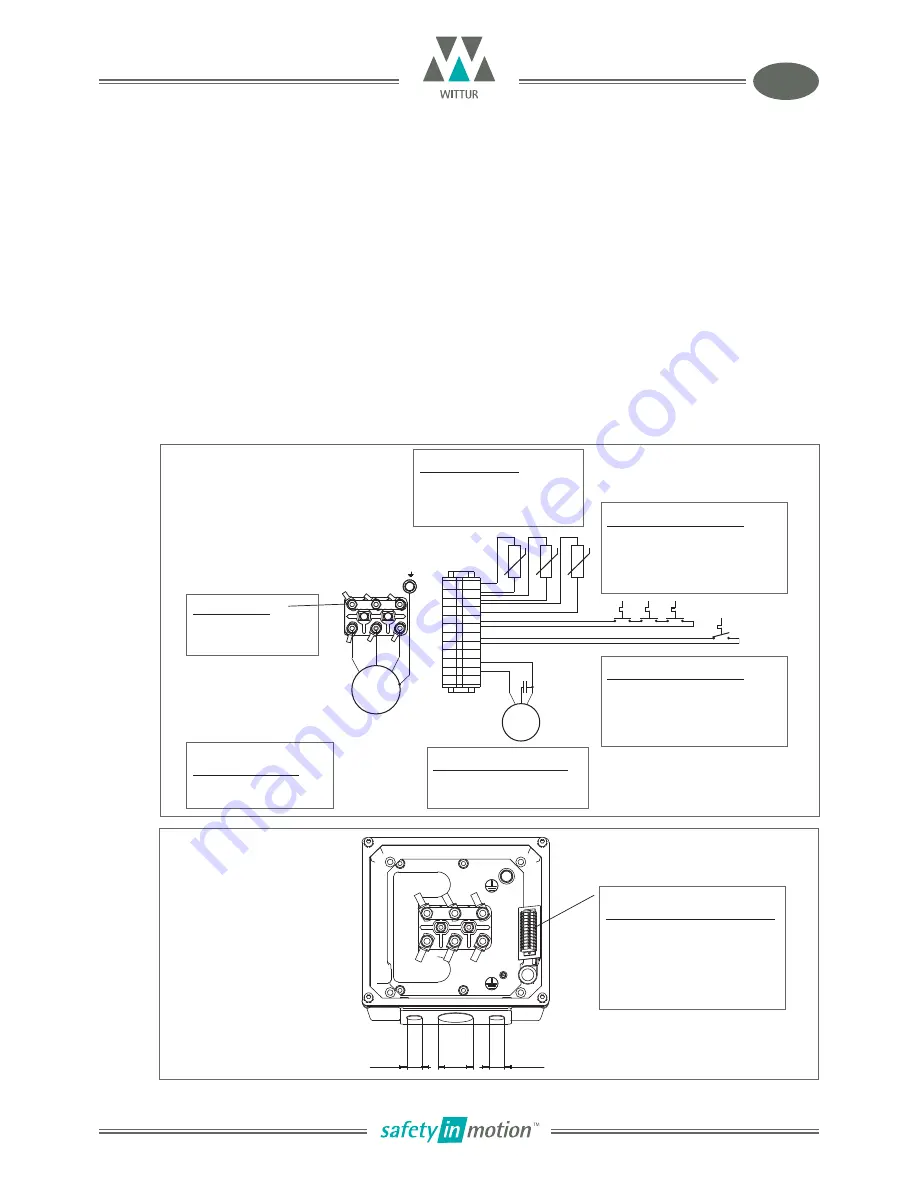

4.2.2. Motor connection / Winding protection / Separately driven fan

• The electrical connection of the motor, the separetely driven fan and the winding sensors to the mains is

made in the motor terminal box.

• The motor cable must be shielded. Ensure that the cable shield contacts the frame over a large area at both ends.

• The motor phases U1, V1 and W1 must be connected correctly to the corresponding phases of the inverter;

they must not be interchanged.

• We recommend using a inverter with a switching frequency of 8 kHz.

• The thermocouples installed in the winding such as PTC thermistor detectors and thermostatic switches must

be evaluated in the control system or frequency inverter to protect the motor from overtemperature.

• The separately driven fan must be properly connected and operated. If required, it can be switched in

dependence of the temperature by means of thermal switch S4 (relay must be used).

Terminal strip for fan and

winding protection connections

WAGO 260

Cable cross-section:

1,5 mm

2

Stripping length required:

8-9 mm

Terminal box -

screwed cable entry

2 x tapped hole M 20 x 1,5

1 x tapped hole M 75 x 1,5

Separately driven fan

F

D2E 146 AZ03-

230 V / 50 Hz / 1,44 A

Thermostatic switch

S4

1 x S02.60.05 ... (60°C)

(250 V AC / 2,5 A / cos

= 1)

- embedded in the motor winding

- e. g. for fan control

Thermostatic switch

S1

3 x S01.130.05 ... (130°C)

(250 V AC / 2,5 A / cos

= 1)

- embedded in the motor winding

- pre-warning overtemperature

PTC Thermistor

T

3 x STM-150.ES ... (150°C)

- embedded in the motor winding

- for motor protection

Terminal studs

M 16 (max. tightening

torque: 30 Nm)