Annex to the EC Type-Examination Certificate

No. EU-BD 1030 of 2017-01-18

Note: The English text is a translation of the German original. In case of any discrepancy, the German version is valid only.

Page 2 of 3

2

Conditions

2.1

Above mentioned safety component represents only a part at the protection device against over-

speed for the car moving in upwards direction and unintended car movement. Only in combination

with a detecting and triggering component in accordance with the standard (two separate compo-

nents also possible), which must be subjected to an own type-examination, can the system created

fulfil the requirements for a protection device.

2.2

The installer of a lift must create an examination instruction to fulfil the overall concept, add it to the

lift documentation and provide any necessary tools or measuring devices, which allow a safe ex-

amination (e. g. with closed shaft doors).

2.3

The single brakes have to be arranged symmetrically around the circumference of the brake disc.

In order to comply with the redundancy required in section 5.6.6.2 of EN 81-20:2014 (D), at least

two braking circuits (single brake actuator) must be used.

2.4

Where more than two braking circuits are used, redundancy requirements necessitate that a suffi-

cient braking effect as outlined in section 5.9.2.2.2.1 of EN 81-20:2014 (D) is still maintained if one

of the braking circuit fails. It is not assumed that two braking circuits will fail simultaneously.

2.5

The manufacturer of the drive unit must provide calculation evidence that the connection traction

sheave – shaft – brake disc and the shaft itself is sufficiently safe, if the brake disc is not a direct

component of the traction sheave (e. g. casted on). The shaft itself has to be statically supported in

two points.

The calculation evidence must be enclosed with the technical documentation of the lift.

2.6

The setting of the brake force has to be secured against unauthorized adjustment (e. g. sealing

lacquer).

2.7

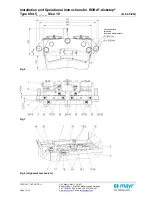

The identification drawing no. E08810000100261 and E08910003000261 including stamp dated

2017-01-18 shall be included to the EU type-examination for the identification and information of

the general construction and operation and distinctness of the approved type.

2.8

The EU type-examination certificate may only be used in combination with the corresponding an-

nex and enclosure (List of authorized manufacturer of the serial production). The enclosure will be

updated immediately after any change by the certification holder.

3

Remarks

3.1

A code number for the manufacturer relevant features and the design characteristics which are not

directly part of the type-examination will be marked at the blank in the type designation RSD Size

10 / 894.5 _ _ . _ _ and RSD Size 10 / 894.7 _ _ . _ _ (e. g. with/without damping, kind of the man-

ual brake release device, connecting cable).

3.2

In the scope of this type-examination it was found out, that the brake device also functions as a

brake for normal operation (using at least two single brakes), is designed as a redundant system

and therefore meets the requirements to be used also as a part of the protection device against

overspeed for the car moving in upwards direction and as braking element as part of the protection

device against unintended car movement.

3.3

Checking whether

the requirements as per section

5.9.2.2 of EN 81-20:2014 (D)

have been

com-

plied

with is not part

of

this type examination.

3.4

Other requirements of the standard, such as reduction of brake moment respectively brake force

due to wear or operational caused changes of traction are

not part

of

this type examination.