Installation and Operational Instructions for ROBA

®

-diskstop

®

Type 894.5_ _._ _ Size 10

(B.8.4.5.EN)

23/03/2017 TK/TL/GC/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 15 of 16

www.mayr.com

, E-Mail:

info@mayr.com

Maintenance

The ROBA

®

-diskstop

®

is mainly maintenance-free.

The friction lining pairing is robust and wear-resistant. This

ensures a particularly long service lifetime of the brake.

However, the friction linings are subject to functional wear.

Therefore, please carry out regular friction lining inspections.

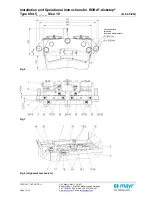

The friction pads (4) must be replaced when air

gap “a” > 1.8 mm (Fig. 2) is reached between

the coil carrier (1) and the armature disk (2) on

a warm brake.

Replacement of the friction pads (4) and all other maintenance

work must be carried out at the place of manufacture.

Guidelines on Brake De-installation

Before carrying out brake de-installation (e.g.

brake change), all cap screws (17) must be

loosened.

Information on the Components

The

friction material

contains different inorganic and organic

compounds, which are integrated into a system of hardened

binding agents and fibres.

Possible hazards:

No potential dangers have been recognised so far when the

brake is used according to its intended purpose. When grinding

in the friction linings (new condition) and also in case of

EMERGENCY STOP braking actions, functional wear can occur

(wear on the friction linings); on open brake designs, fine dust

can be emitted.

Classification: Hazardous property

Attention: H-classification: H372

Protective measures and rules of behaviour:

Do not inhale dusts

Vacuum the dusts at the point of origin (tested suction devices,

tested filters acc. DIN EN 60335-2-69 for dust classes H;

maintenance of the suction devices and filter replacement at

regular intervals).

If local dust suction is not possible or is insufficient, the entire

work area must be ventilated using appropriate technology.

Additional information:

This friction lining (asbestos free) is not a dangerous product in

terms of the EU Directive

Cleaning the Brake

Do not clean the brake using compressed air,

brushes or similar devices!

Use a suction system or wet towels to clean off the brake

dust.

Do not inhale brake dust (wear safety gloves / safety

goggles)

In case of dust formation, a dust mask FFP 2 is

recommended.

Disposal

Our electromagnetic brake components must be disposed of

separately as they consist of different materials. Please also

observe the relevant authority regulations. Code numbers may

vary according to the disassembling process (metal, plastic and

cables).

Electronic components

(Rectifier / ROBA

®

-switch / Microswitch):

Products which have not been disassembled can be disposed of

under Code No. 160214 (mixed materials) or components under

Code No. 160216, or can be disposed of by a certified disposal

firm.

Brake bodies made of steel with coil/cable and all other

steel components:

Steel scrap

(Code No. 160117)

All aluminium components:

Non-ferrous metals

(Code No. 160118)

Friction pads (steel or aluminium pads with friction linings):

Brake linings

(Code No. 160112)

Seals, O-rings, V-seals, elastomers, terminal boxes (PVC):

Plastic

(Code No. 160119)