Maintenance and repair

INTORQ | BA 14.0201 | 04/2016

32

7.2

Inspections

Important notes

To ensure safe and trouble-free operations, the spring-applied brakes must be checked at regular intervals

and, if necessary, be replaced. Servicing will be easier at the plant if the brakes are made accessible. This

must be considered when installing the drives in the plant.

Primarily, the required maintenance intervals for industrial brakes result from their load during operation.

When calculating the maintenance interval, all causes for wear must be taken into account,

32. For

brakes with low loads (such as holding brakes with emergency stop function), we recommend a regular in-

spection at a fixed time interval. To reduce costs, the inspection can be carried out along with other regular

maintenance work in the plant.

Failures, production losses or damage to the system may occur when the brakes are not serviced. Therefore,

a maintenance strategy that is adapted to the particular operating conditions and brake loads must be de-

fined for every application. For the spring-applied brakes, the maintenance intervals and maintenance oper-

ations listed in the table below must be followed. The maintenance operations must be carried out as

described in the detailed descriptions.

7.2.1

Maintenance intervals

The spring-applied brake must be checked during the prescribed inspections of the drive system in which it

is installed.

❚

The service life of the brake before replacement does not only depend on the number of emergency

brakings.

❚

The wear of the brake friction linings varies depending on the operating conditions.

❚

The friction work possible before replacement decreases with every braking when the switching energy

increases.

7.2.2

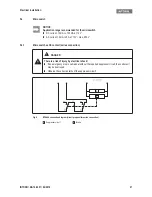

Checking the air gap

1. Switch on the current for the brake (see

25).

2. Use a feeler gauge to check the air gap "s

L

" between the brake disc and friction lining. It must not exceed

the maximum permissible air gap "s

Lmax

", as specified in the table (

14).

3. Switch off the current.

4. Reconnect the motor.

DANGER

Make sure that you remove all loads from the drive. Otherwise, there is a risk of an accident.

The motor must not run while the spring-applied brake is being checked.