Gearless Lift Machine

WSG-TB

Operating Instructions

Subject to changes without notice ! Subject to changes without notice !

EN

6.

Operation and maintenance

6.1. General

• The regulations concerning operation, maintenance and inspection pursuant to the applicable safety regula -

tions for lift construction such as DIN EN 81-20, DIN EN 81-50, LD 2014/33/EU and other relevant regulations

are to be strictly observed.

• The operator is responsible for ensuring that the motor is installed properly and in accordance with the safe -

ty requirements, as well as for its inspection and maintenance as specified in the applicable regulations.

• The proper maintenance of gearless lift machines requires adequately trained specialist personnel and special

devices and tools.

• Repairs other than those described in these operating instructions are not to be carried out by the lift fit -

ter/maintenance technician for liability reasons.

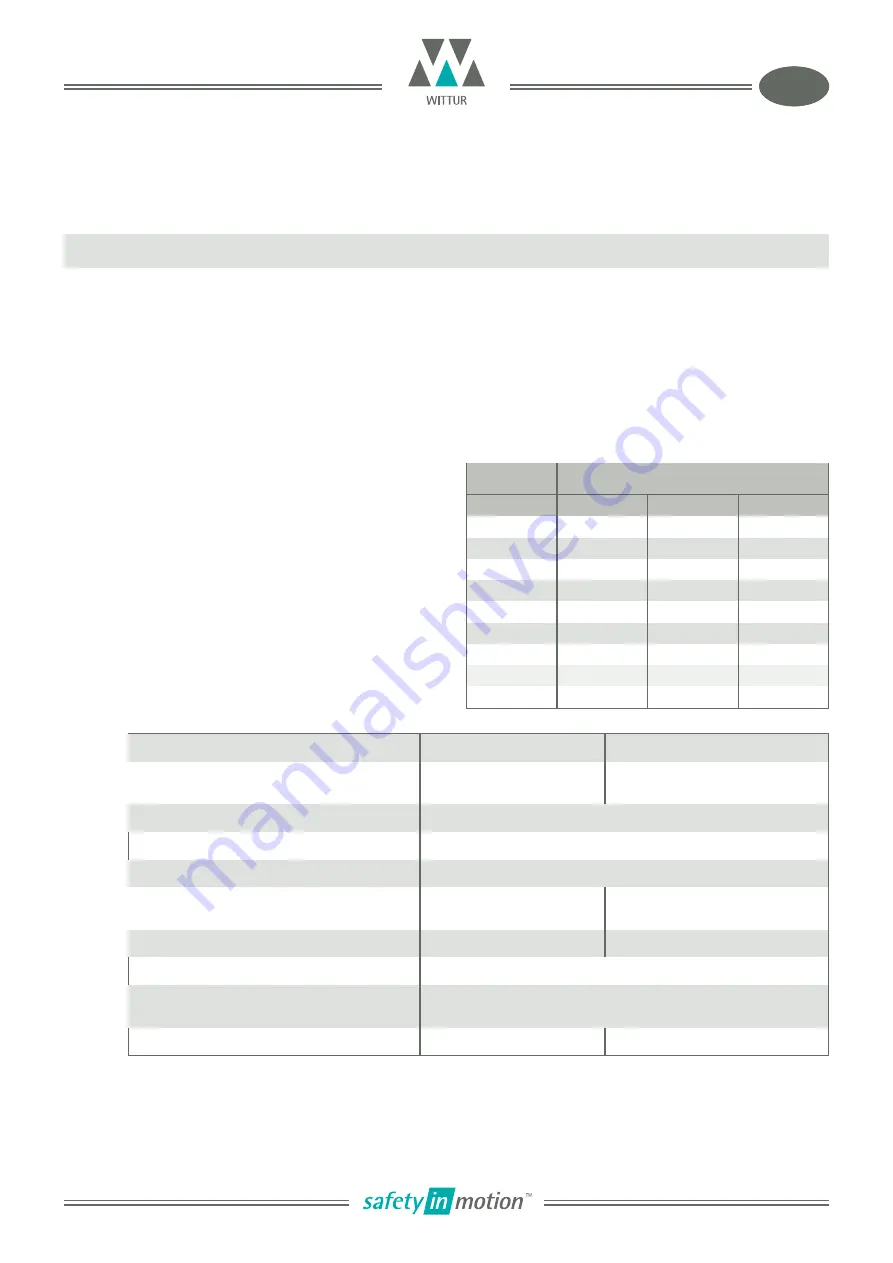

Bolt/screw tightening torques

• When performing any work on the machine or

replacing parts, make sure that the specified

bolt/screw strength class and the tightening

torques are observed (see table).

• Secure the bolts/screws with "omnifit 100" or a

similar product against accidental loosening.

6.2. Maintenance intervals

Dimension

Tightening torque [Nm]

Strength class

8.8

10.9

12.9

M4

2,8

4,1

4,8

M5

5,5

8,1

9,5

M6

9,6

14

16

M8

23

34

40

M10

46

67

79

M12

79

115

135

M16

195

290

340

M20

395

560

660

M24

680

970

1150

Check the brake air gap

every six months

see the brake operating instructions

Check the proper functioning of the brakes and the

brake monitoring switches

every six months

see the brake operating instructions

Check the bearing noise

every six months

Regrease the bearings

see section 6.3

Check the traction sheave for wear

every six months

Make a visual check of the fasteningbolts/screws on

the frame, brake and traction sheave

every six months

see section 6.1

Check the electrical cables

every six months

see section 4.2.

Check the rope slip-off guard

every six months

Check the guards and safety devices for their condi-

tion and safe functioning

every six months

Clean the external machine surfaces

as required

6.3. Regreasing the bearings

The anti-friction bearings have been provided with a grease filling at the factory that is sufficient for the

planned service life of the machine. Under normal operating conditions, regreasing is not required or recom -

mended.

Gearless Lift Machine

WSG-TB

Operating Instructions

Code

GM.8.004610.FR

Date

14.05.2018

Statut

0.01

Page

17

Subject to changes without notice ! Subject to changes without notice !

EN

Summary of Contents for WSG-TB.3 series

Page 29: ......

Page 30: ......

Page 31: ......

Page 33: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 95: ...Notes INTORQ BA 14 0197 04 2016 48 Notes...

Page 144: ...Notes INTORQ BA 14 0210 12 2016 48 Notes...

Page 145: ...Notes INTORQ BA 14 0210 12 2016 49...

Page 146: ...Notes INTORQ BA 14 0210 12 2016 50...

Page 147: ......