21.05.2015

E

Gearless Synchronous Lift Machines

WSG09.X

Operating and maintenance manual J40003

Page 19

Date

Version

Subject to changes without notice!

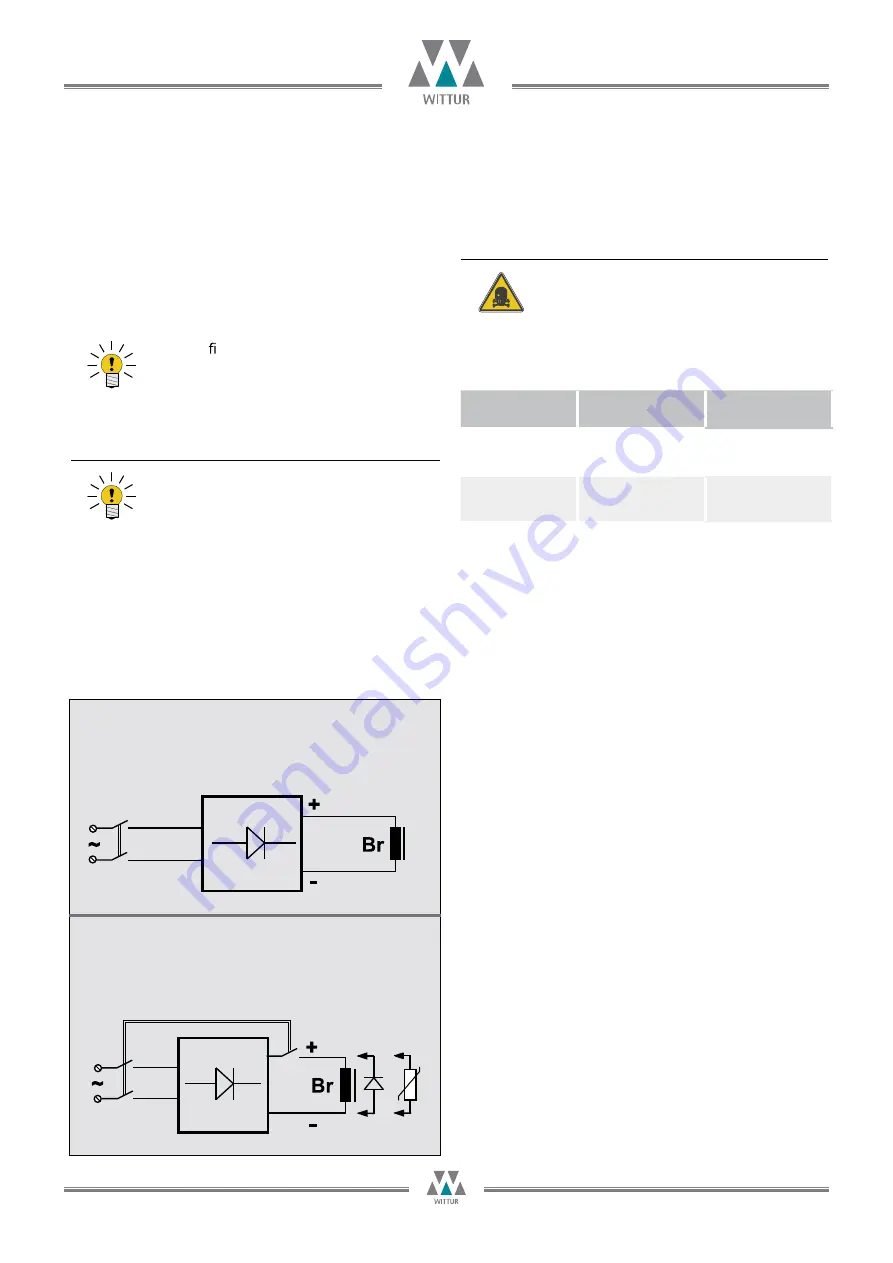

(emergency stop) or during an inspection from the d.c. side,

since this ensures a faster braking effect with the car being

stopped earlier.

It is therefore recommended to use 2 separate

contactors for

the brake control circuitry ,

one of which switching at the d.c.

side, the other one at the a.c. side.

D.c. side switching

r

Noisy switching.

r

Burn-up protection for switching contact required.

(e.g. varistor, free-wheeling diode)

r

Fast application of the brake.

A.c. side switching

r

Low-noise switching of the brake.

r

No protective measures required for switching contact.

r

Slow application of the brake.

Attention: schematic diagram!

Attention: schematic diagram!

10.4. Brake

The brakes are supplied and held with

110V DC .

75-80V DC

.

The recti er has to be prepared by customer.

Following is two recommend solution for the

brake switching which must be realized by the

control circuit from customer controller.

Note on the use of d.c./a.c. side switching:

A.c. side switching is recommended for nor-

mal operation, since the lift machine is then

decelerated in a controlled manner to zero speed

and the switching noise of the brake is negligible.

Note

Note

for holding voltage is preferred for best performances in tem

-perature rise.The connecting contacts for the micro-switches

which monitor the brakes are also accommodated in this term

-inal box.

Monitoring the brakes

The switching state of the brakes is monitored

using dust-proof micro switches with gold

contacts. Both NC and NO contact is prepared

in terminal box. Please refer the connection

advice in the box for connecting according to

request of the control system as following,

Connect

Power on

the brake

Power off

the brake

C1-O1

C2-O2

open

close

C1-S1

C2-S2

close

open

Danger