24

Original operation manual

2K GEL UNIT

2KGel_14025_25015_BAoDB_en_1701 • rs

Transport, installation, and assembly

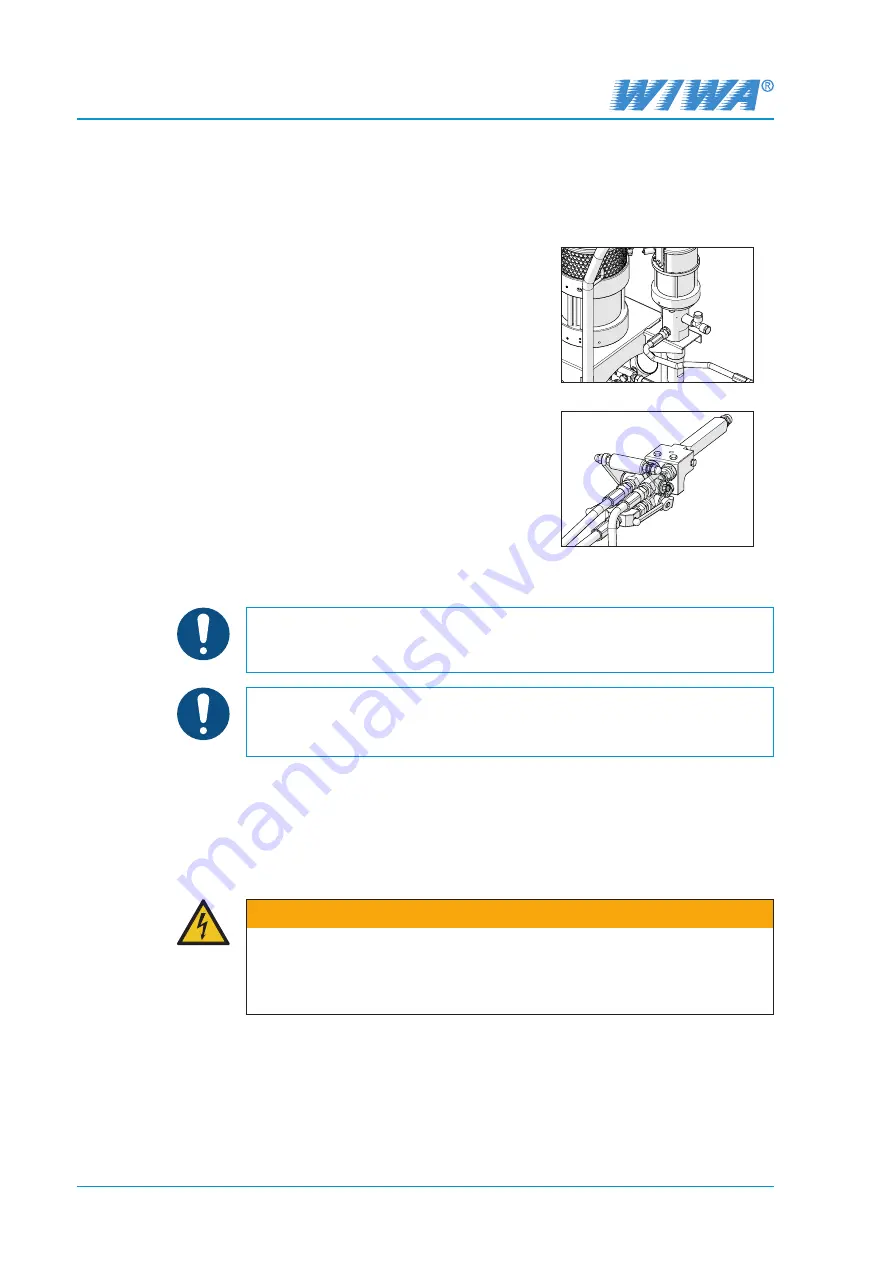

4.3.2 Installing the flushing agent hose

Depending on the machine type, the

2K GEL UNIT

is equipped with a flushing

agent pump.

1.

Connect the flushing agent hose

marked yellow to the material outlet of

the flush pump.

Fig. 16: Connection to flush pump

2.

Connect the other hose end

to the distributor of the mixing unit.

Fig. 17: Connection to mixing unit

4.3.3 Connecting the compressed air supply

To ensure the required quantity of air, the compressor output must comply

with the air requirement of the machine, and the diameter of the air supply

hoses must match the connections.

Operation with contaminated or moist compressed air leads to damage in

the machine's pneumatic system.

➤

Only use air that is dried, and free of oil and dust!

1.

Make sure that all compressed air regulators are turned down fully and that

the compressed air shut-off valve is closed.

2.

Connect the compressed air line to the compressed air connection of the

compressed air regulator/air supply.

4.3.4 Grounding the machine

WARNING

The high flow velocities during the injection process can result in an electro-

static charge.

Static discharges can result in fire and explosions.

➤

Make sure that the machine is correctly grounded!

The ground cable is already connected to the machine at the time of delivery.

To ground the machine, connect the terminal of the ground cable to an

electrically conductive object outside of potentially explosive areas.