Device description

Original operation manual

HIGH PRESSURE CLEANER

HPC_BADBK_en_1805 • rs

21

No. Designation

7

Connection for the material hose

8

Fluid pump

9

Suction for the cleaning solution

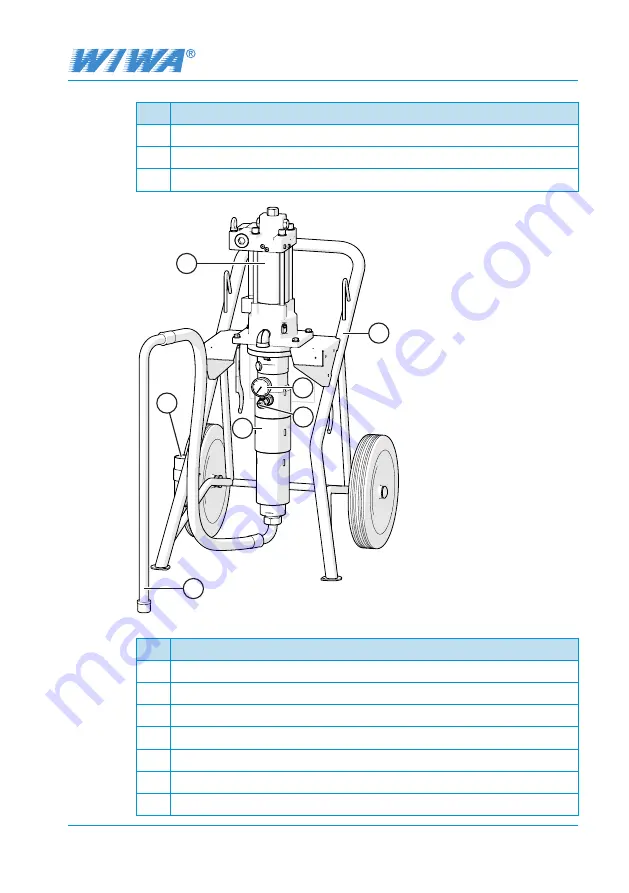

Fig. 8

: Type 60001

1

3

6

4

5

7

2

No. Designation

1

Hydraulic motor

2

Cart

3

Pressure gauge for displaying the material pressure

4

Connection for the material hose

5

Fluid pump

6

Mounting for the suction

7

Suction for the cleaning solution