Maintenance

Original operation manual

HIGH PRESSURE CLEANER

HPC_BADBK_en_1805 • rs

36

6.2.4 Checking the compressed air, hydraulic and material hoses

Check the compressed air, hydraulic and material hoses weekly for

externally visible damage, such as kinks, cracks, signs of wear or bulges.

Improper use and impermissible stress are the most frequent causes of

damage. Damaged hoses must be replaced immediately.

Hose lines are subject to a natural aging even with proper use and

permissible stress. Their duration of use is thereby limited. Therefore,

the compressed air, hydraulic and material hoses must be checked by a

specialist every 3 years.

The duration of use of a hose line, including any possible storage

duration, should not exceed 6 years.

The manufacturing date of a hose line (month/year) is stamped on the

ferrule.

6.3

Operating fluid

Operating fluid

WIWA order number

Release agent (0.5 l) ¹

0163333

Locking agent (50 ml) ²

0163333

Lubricant (acid-free grease, 0.4 kg) ²

0163333

Lubricant for stainless steel ²

0163333

¹ The release agent is also available in larger containers upon request

²

Materials required during maintenance and repair work (see information

in the spare parts lists)

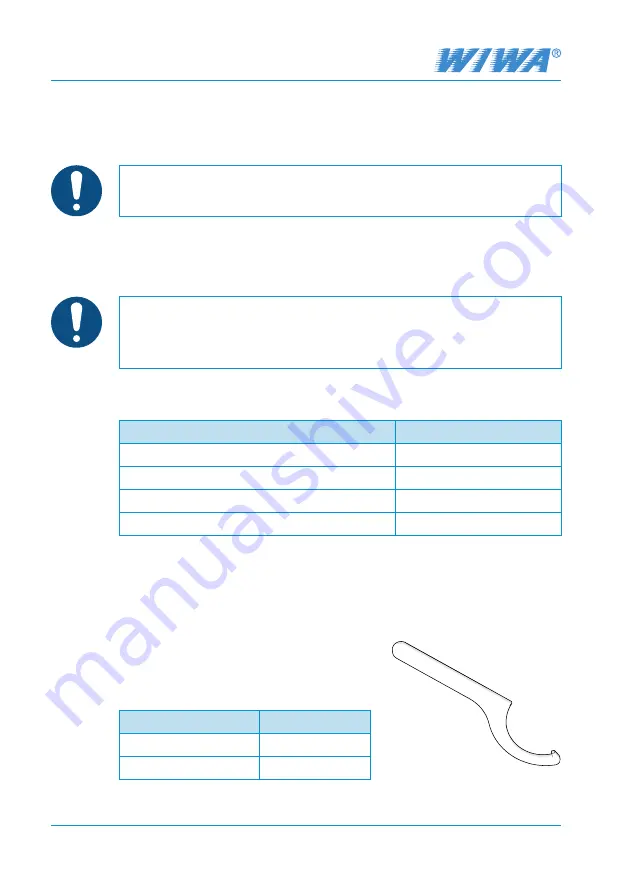

6.4 Special tool

The device types 230027, 270049,

333037 and 60001 are delivered with

2 hook wrenches for the assembly and

disassembly of the fluid pump.

Wrench size

Art. no.

80 / 90 mm

0660287

110 / 115 mm

0660288

Fig. 21

: Hook wrench