30

Original operation manual

AIRCOMBI

AirCombi_BAoDB_en_1701 • rs

Transport, installation and assembly

1.

Ensure that

➤

the compressed air shut-off valve is closed,

➤

the air regulator has been turned down fully.

2.

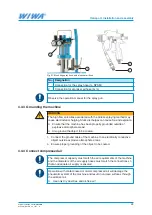

Connect the air hose to the air inlet of the pressure regulator (see Fig. 22)

or to the maintenance unit (see Fig. 23), depending on the version.

Fig. 22:

Connecting compressed air to

the dual air pressure regulator

Fig. 23:

Connecting compressed air to

the maintenance unit