About the machine

3

Translation of the original operation manual

15

15

•303_208176_1004_en•ski

3.3

Machine surroundings

Emissions

It is possible for solvent vapors to occur, depending on the materials used. Therefore,

please ensure the workplace is sufficiently ventilated in order to avoid damage to health

and property.

Always

observe the processing information given by the material manufac-

turer.

The sound pressure level of the equipment is below 85 db(A).

Nevertheless, appropriate means of noise protection should be made available to the

operating staff. The operator is responsible for compliance with the rules covering the

prevention of accidents due to „noise“ (BGV B3). Therefore, pay special attention to

the environmental conditions at the site, e.g. noise can be increased if the machine is

installed in or on hollow bodies.

3.4

Transport

➤

Disconnect the unit from its power sources (air, electricity) before moving, even for

small distances.

➤

Empty the unit of coating prior to transportation.

➤

Attention when lifting with a crane!

Verify at loading of the machine the sufficient load capacity of the lifting devices and

the load holding devices.

Measures and weight of the machine are shown in the machine card.

➤

The unit should only be suspended using the foreseen lifting holes.

Keep care to have free hanging ropes, if necessary use yoke suspension. The length

of the lifting ropes should be at least 3 meter.

The number of lifting struts (picture 3.1, pos.2) and fork lifting slats (picture 3.2, pos.1)

can vary depending on the size of the unit. Fix safely all the lifting devices to the lifting

struts.

Attention! Danger of tilting! Keep care to suspend with uniform repartition of the load

to avoid tilting.

➤

With forklifting pockets:

When using fork lifter the length of fork must be sufficient

(minimum 135 cm). The fork must enter all the fork pockets on the 2K frame (picture

3.2, pos.1).

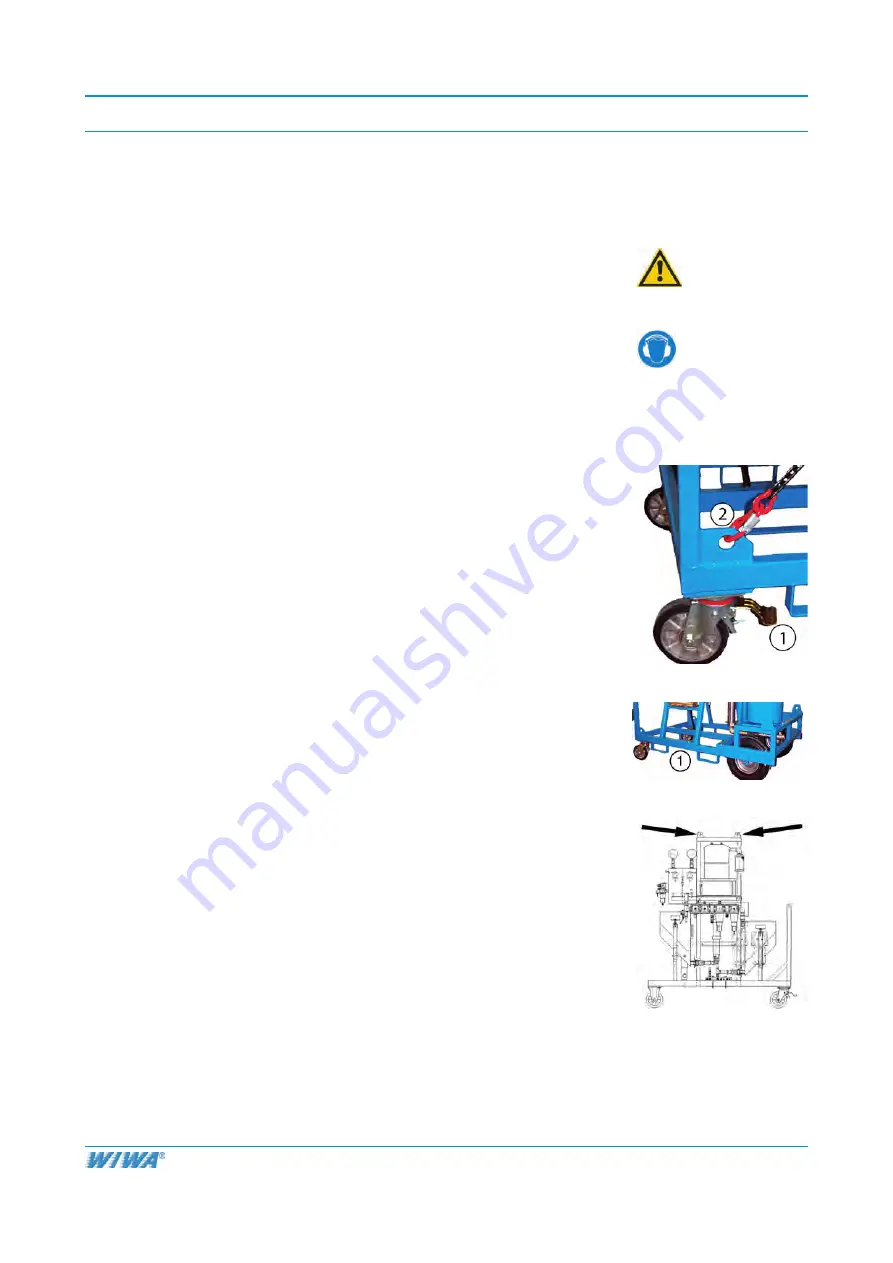

➤

With crane eyes:

If you lift the unit with a crane, take care of free hanging cables.

The length of the lifting cables must to be at least 3 meters. Attach the crane eyes

securely on the mounting strut (picture 3.3).

➤

Don’t move any additional items when lifting and transporting the unit (e.g. paint

container).

Remove all loose parts from the unit (e.g. tools).

Never stand under swinging loads or in the loading area.

Danger to life!

➤

Secure the load on the transportation vehicle against slippage and falling down.

➤

Parts or equipment dismounted for transportation purposes must be properly re-

mounted by a specialist according to application before start-up.

Picture 3.1

Picture 3.2

Picture 3.3