5

Commissioning

30

Translation of the original operation manual

•303_208176_1004_en•ski

➤

Increase the air inlet pressure to allow the dispensing unit to overcome the backpres-

sure.

➤

Flush until clean material is emitted.

➤

Close the lever of the dispensing unit.

➤

Exchange the containers for clean measuring jugs.

➤

Open the lever on the dispensing unit and fill the desired amount of material. Return

the levers to the “OFF” position afterwards.

➤

Set the air regulator (pos. 2.2) on the main pump back to 0 bar.

➤

Check the mixing ratio based on the amount of each material filled.

4. Step: Preparation for spraying

Settings on the mixer (Spray)

➤

Turn the lever on the external mixer:

➤

SPRAY (pos. 13.2) to “OPEN”.

➤

FLUSH (pos. 13.3 A / B) to “CLOSED”.

➤

CIRCULATE (pos. 13.1) to “CLOSED”.

➤

Now slowly set the air regulator (pos. 2.2) of the main pump to the desired spraying

pressure.

➤

Unlock the safety catch on the spray gun* and trigger it to balance the pressure of

both components.

➤

Check the contact gauge (pos. 3) for the A and B component until it shows the same

pressure.

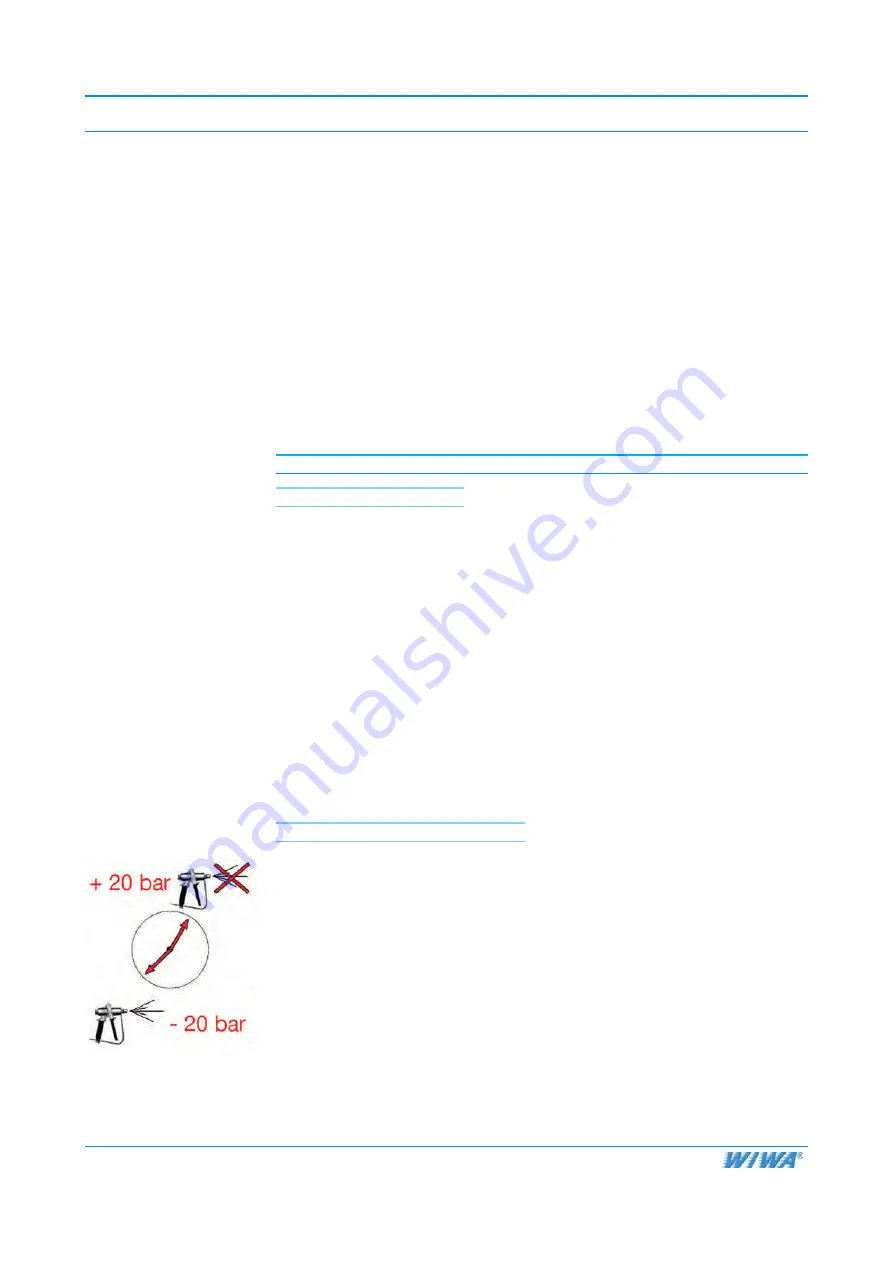

Setting the limits on the contact gauge

On the pressure & metering monitor (pos. 1), you can set the limits in which the A- and B-

components are being monitored.

➤

Using the key supplied, now set the pointers (red) on the two pressure gauges (pos.

3) by pressing in the key and turning the adjusting pin for the pointer:

➤

Upper Red Pointers when gun is closed (stall pressure):

approx. +20bar

➤

Lower Red Pointers upon gun triggering (spray pressure):

approx. -20bar