Operation

6

Translation of the original operation manual

35

35

•303_208176_1004_en•ski

Task: The work on the unit is going to be interrupted or completely stopped.

Flush components, which were contaminated by mixed material within the pot

life given by the manufacturer!

If you are stopping the work on the machine for a longer time you should follow

the instruction listed in the chapter “Complete Cleaning”.

➤

Make certain that the suction assembly of the flush pump is placed in the thinner and

you set a pressure of 3 - 6 bar on the air regulator of the flush pump (pos. 6.1), depend-

ing of the length of the hoses.

➤

Turn back air regulator (pos. 10.1) of the feed pumps back to 0 bar.

➤

Turn back air regulator (pos. 2.2) of the main pump to the left until it eases.

➤

Turn switch MANUAL/AUTOMATIC (pos. 1.3) on the control panel to “MANUAL”.

➤

Trigger gun shortly to pressure release the equipment.

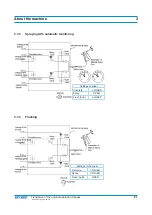

Settings on the mixer (flush)

➤

Turn lever on the external mixer:

➤

SPRAY lever (pos. 13.2) to “CLOSED”.

➤

FLUSH (pos. 13.3 A / B) to “OPEN”.

➤

CIRCULATE lever (pos. 13.1) to “CLOSED”.

➤

By simultaneously triggering the spray gun*s until clean solvent appears, the area

between mixer to spray gun* is flushed.

➤

Close on the external mixer each ball valve of the A- and B- component (pos. 13.3 ) sepa-

rately for about 5 - 15 sec. .This will insure the optimal cleaning of the area around

the ball valves.

Repeat this procedure for about 3 times, but at least until clean thinner is emitted.

The material which remains in the system leading up to the mixing block (component

A and B) does not need to be flushed, as no hardening occurs.

➤

Turn the regulator (pos. 6.1) of the flush pump to 0 bar.

CAUTION!

The flush pump has to

be ready at all times

during the working

process.

At all times it must be

possible to flush com-

ponents, which were

contaminated by mixed

material,

within the

given pot life

!