Disturbances during operation and trouble-shooting

9

Translation of the original operation manual

47

47

•303_208176_1004_en•ski

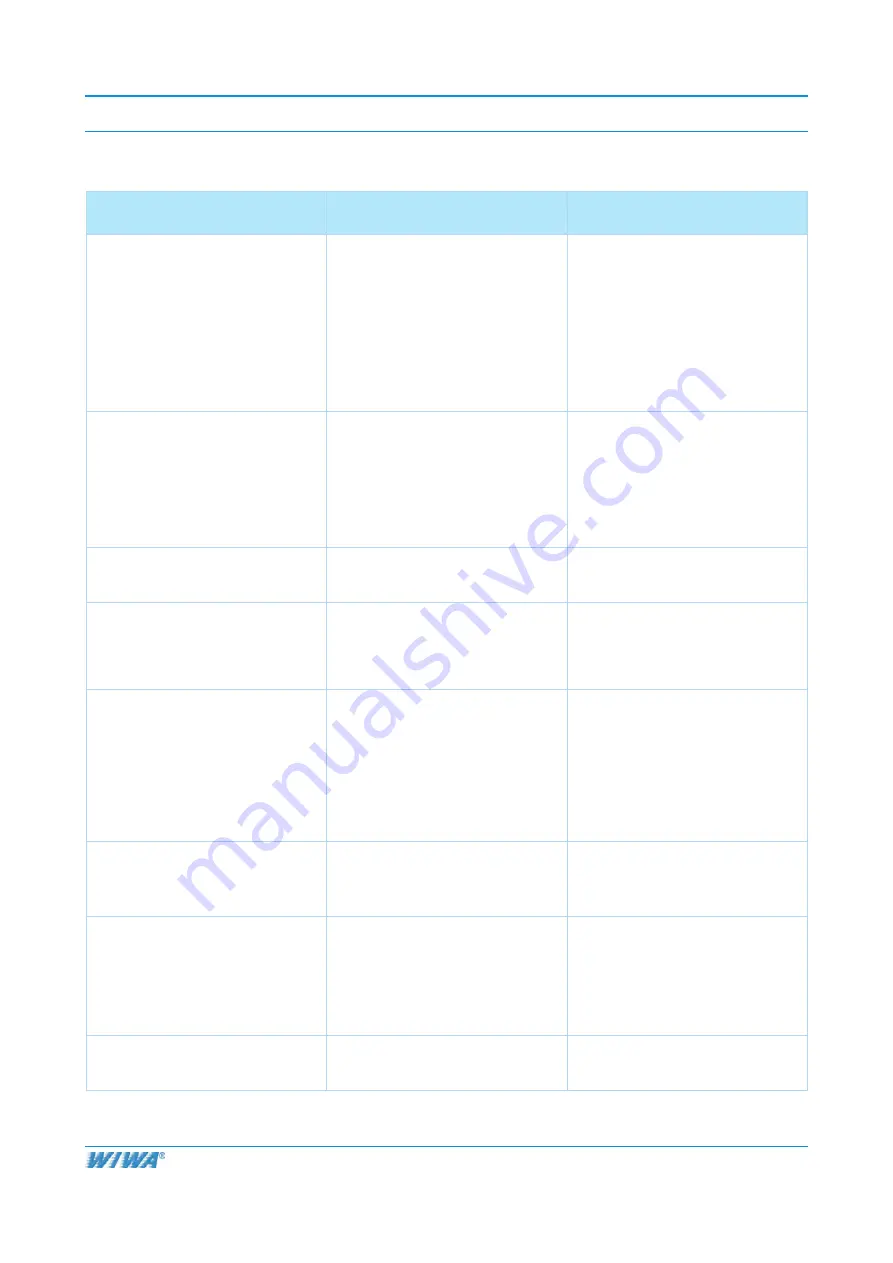

Faults

Probable Causes

Remedies

22. The equipment can not be started,

although the pressure gauge at

the air maintenance unit shows

pressure.

➤

Ball valve at the air maintenance

unit is closed.

➤

The air supply of the control panel

is interrupted.

➤

The filter pressure regulator at the

control panel is adjusted incor-

rectly.

➤

The STOP button has been

pressed and locked.

➤

Open ball valve at the air mainte-

nance unit.

➤

Ensure sufficient air supply of the

control panel.

➤

Adjust pressure to 8 - 10 bar.

➤

Unlock the STOP button.

23. The equipment can only be

started for a short time (only as

long as the START button is being

pressed).

➤

Switch „MANUAL/AUTOMATIC“

has been turned to „AUTOMATIC“.

➤

The material pressure of one com-

ponent is above the red needle of

the pressure control.

➤

One of the pressure gauges deliv-

ers a wrong signal.

➤

Turn „MANUAL/AUTOMATIC“

switch to „MANUAL“

➤

Release the material pressure.

➤

Replace the defective pressure

gauge.

24. A contact pressure gauge shows

pressure, although the equipment

has been released from pressure.

➤

Pressure gauge is defective.

➤

Replace the defective pressure

gauge.

25. The contact gauge shows no pres-

sure or only to a certain value.

The unit is supplied with air. The

black indicator is fixed on one

value and is not moving.

➤

Pressure gauge is defective (Oil is

leaking out of the gauge).

➤

Replace the defective pressure

gauge.

26. When pressing the STOP switch,

the equipment does not stop.

➤

Air inlet valve and air outlet valve

at air inlet of air motor do not work

properly.

➤

STOP switch is defective.

➤

Ensure that pneumatic hoses

are connected according to the

diagram.

➤

Check function of valves (dia-

phragm is possibly swollen as

a result of using of the wrong

pneumatic oil).

➤

Replace defective parts.

27. The 2-K unit does not operate

when the switch is turned to

„SPRAY“ or to „FLUSH“.

➤

Pot life has been disregarded.

Mixing unit, material hoses and

spray gun* have not been flushed,

and the material has cured.

➤

Try to clean or replace parts which

are clogged by hardened material.

When using automatic valves:

28. Automatic valve functions im-

properly (e.g. the automatic valve

of the hardener opens with the

automatic valve of the flush pump,

while the automatic valve of the

base closes).

➤

Pneumatic hoses have not been

connected properly (e.g. after

repair).

➤

Connect pneumatic hoses accord-

ing to the diagram.

29. Gaskets of (automatic-) valves are

leaking material.

➤

Gaskets are not pre-tensioned

sufficiently or are worn.

➤

Tighten gasket screw when the

equipment is pressure released or

replace packing.