Translation of the original Operation Manual

5-1

•1307_PU280_SV1018DV1020_BAoDB_en•ski

en

5

Commissioning

After assembly in the factory the correct functioning of this machine was checked

with a testing medium.

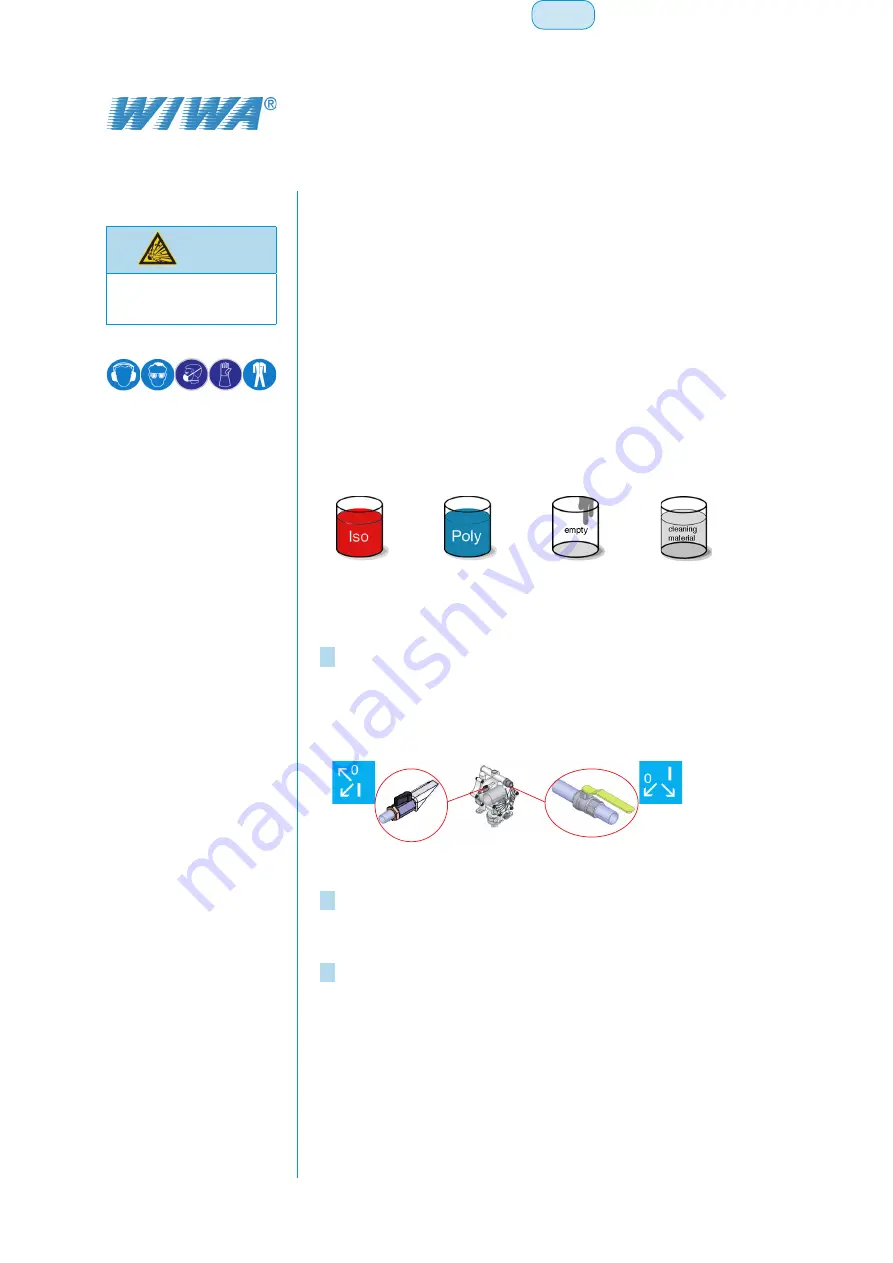

All material hoses and the metering pump must first be filled with the material to

be applied.

The entire system can first be flushed with the cleaning agent recommended by

the material manufacturer and belonging to the material, before it is filled with the

material to be applied, to make sure that the spraying material is not contami

-

nated by the testing medium.

Always wear the specified protective clothes.

The unit has been set up and connected as specified in chapter

1x

1x

2x

2x

(if required)

1.

Prepare the material

➤

Open the bungholes on the material drums.

➤

Insert the feed pumps into the material drums. Ensure secure hold of pumps.

➤

Open the shut-off valves for compressed air and material (optional) on each

feed pump.

Figure 5.1

2.

Dismantle connection block from spray gun see chapter

3.

With optional version with circulation / relief:

➤

Hold the return flow hoses into open containers to catch testing agent / mate

-

rial mix.

➤

Secure the hoses against accidental slipping out.

Attention!

Do not switch on any

heater when using clean

-

ing agents!

Prerequisites

The following is required

Procedure

Summary of Contents for DUOMIX PU280

Page 68: ......