Translation of the original Operation Manual

5-2

•1307_PU280_SV1018DV1020_BAoDB_en•ski

en

Commissioning

4.

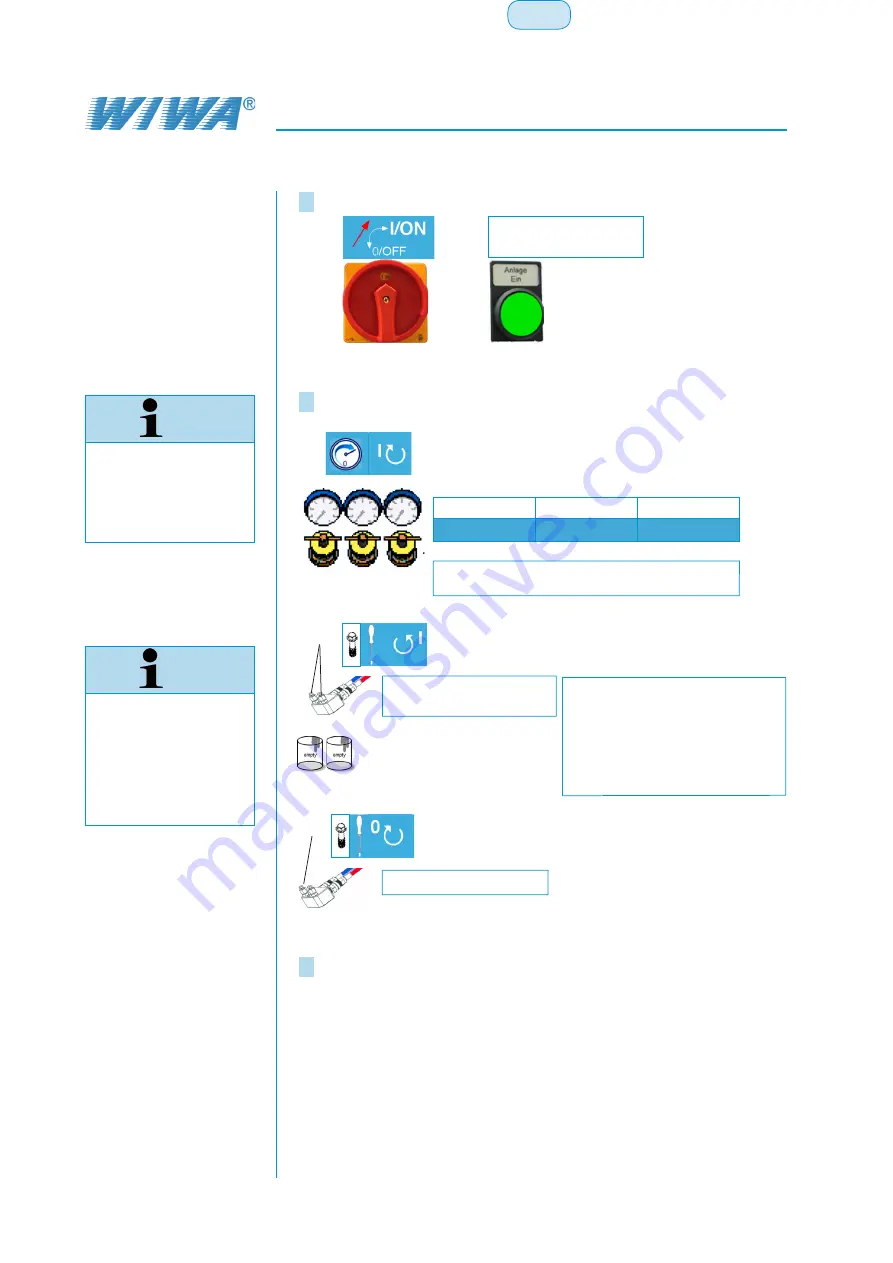

Switch on the equipment

Switching the unit on

(press the green button)

Figure 5.2

5.

Fill the metering pump with material

Both components!

1

1

/

4

to 1

1

/

2

revolutions

Duration: until clean, bubble-free

material starts to run out

For initial filling with feed drums

and initiual cleaning with cleaning

agent: Pump the cleaning agent

completely out of the containers.

Attention!

Ensure slow running of the pump!

Spray Gun

Feed Pump

Proportioner Pump

6 bar/ 87 psi

4 bar/ 58 psi 1 bar/ 14,5 psi

Clean the material outlet!

Figure 5.3

6.

only with optional version with circulation / relief

➤

Open the circulation as described in chapter

Catch the testing medium/material mix in the collecting container.

➤

Connect the circulation as described in chapter

as

soon as clean material starts to run out.

➤

Fasten the return flow hoses to the material drum.

Note!

The specified pressures

are only guide values

and, depending on the

viscosity of the material

or the hose length used

,

may need to be adapted.

Note!

The unit has been

checked with a testing

medium in the factory.

Residues of this material

may still be found in the

system. We recommend

appropriate disposal of

this discharge amount.

Summary of Contents for DUOMIX PU280

Page 68: ......