Original Operation Manual

12-3

•1307_PU280_SV1018DV1020_BAoDB_en•ski

en

Malfunctions and Troubleshooting

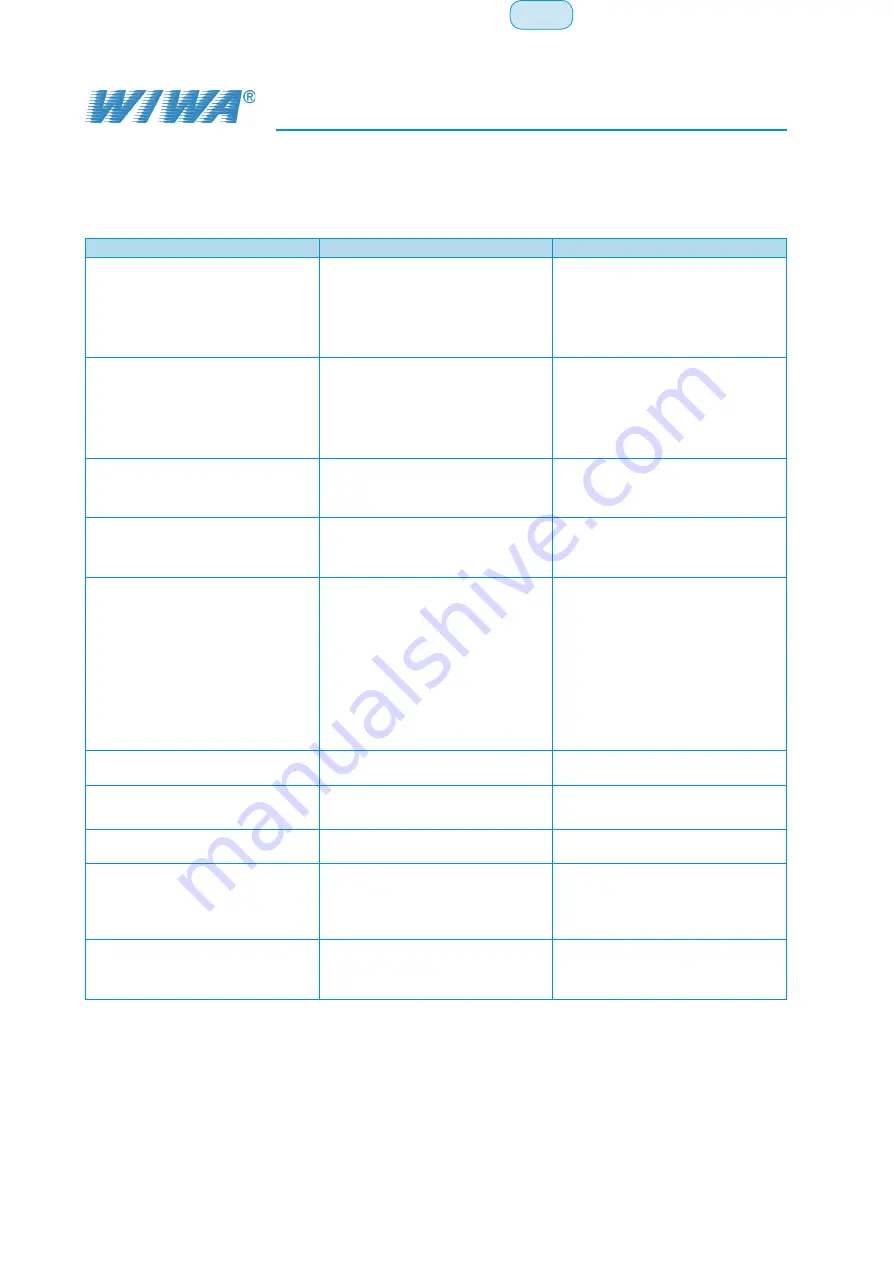

12.2 Troubleshooting on the spray gun

Fault

Possible cause

Remedy

1. The valve rod does not trigger.

➤

No air pressure available.

➤

Insufficient air pressure available.

➤

Rear sealing nut excessively

tightened.

➤

Connect the air supply and open

the air valve.

➤

Set the air pressure to 5,5-9 bar.

➤

Slightly loosen the nut.

2. Spray fog on round jet nozzle,

even though the trigger has not

be actuated.

➤

Screws on front plate loose.

➤

The rear side of the front plate is

soiled.

➤

Mix module bore worn.

➤

Tighten the screws on the front

plate with a spanner.

➤

Clean the front plate and check

for score marks.

➤

Replace the mix module..

3. Increased overspraying

➤

Excessive air flow to the front

cap.

➤

Material pressure set too high.

➤

Reduce the air flow with the

regulator.

➤

Reduce the material pressure.

4. Round spray pattern forms “fin

-

gers” or is deformed.

➤

The round jet nozzle is soiled or

worn.

➤

Clean the round jet nozzle with an

appropriate drill.

➤

Replace the round jet nozzle.

5. Pressure fluctuations.

➤

Mix module inlets and outlets

soiled or worn.

➤

Viscosity of components not

uniform.

➤

Filter element dirty.

➤

Check valves dirty.

➤

Clean the mix module inlets and

outlets with an appropriate drill or

replace the mix module.

➤

Regulate the material tempera

-

ture accordingly.

➤

Clean or replace the filter ele

-

ments.

➤

Clean or replace the check

valves.

6. Gelated or hardened material in

the air channels to the front cap.

➤

Incorrectly directed material, air

in hoses.

➤

Clean or replace the check

valves.

7. Material emerges from the back

side seal.

➤

Sealing nut loose.

➤

Back side seal worn or damaged.

➤

Slightly tighten the sealing nut.

➤

Replace the backside seal.

8. Rapid build up of material on the

round jet nozzle or the front cap.

➤

Insufficient air flow to the front

cap.

➤

Increase the air flow to the front

cap.

9. Spray gun triggers only very

slowly.

➤

O-rings dry or worn.

➤

Wet the spray gun with spray gun

oil.

➤

Replace and lubricate the O-

rings.

10. Pressure loss on air outlet.

➤

Damaged O-rings on slide valve.

➤

Damaged O-ring on piston.

➤

Replace the O-rings on slide

valve.

➤

Replace the O-rings on piston.

Summary of Contents for DUOMIX PU280

Page 68: ......