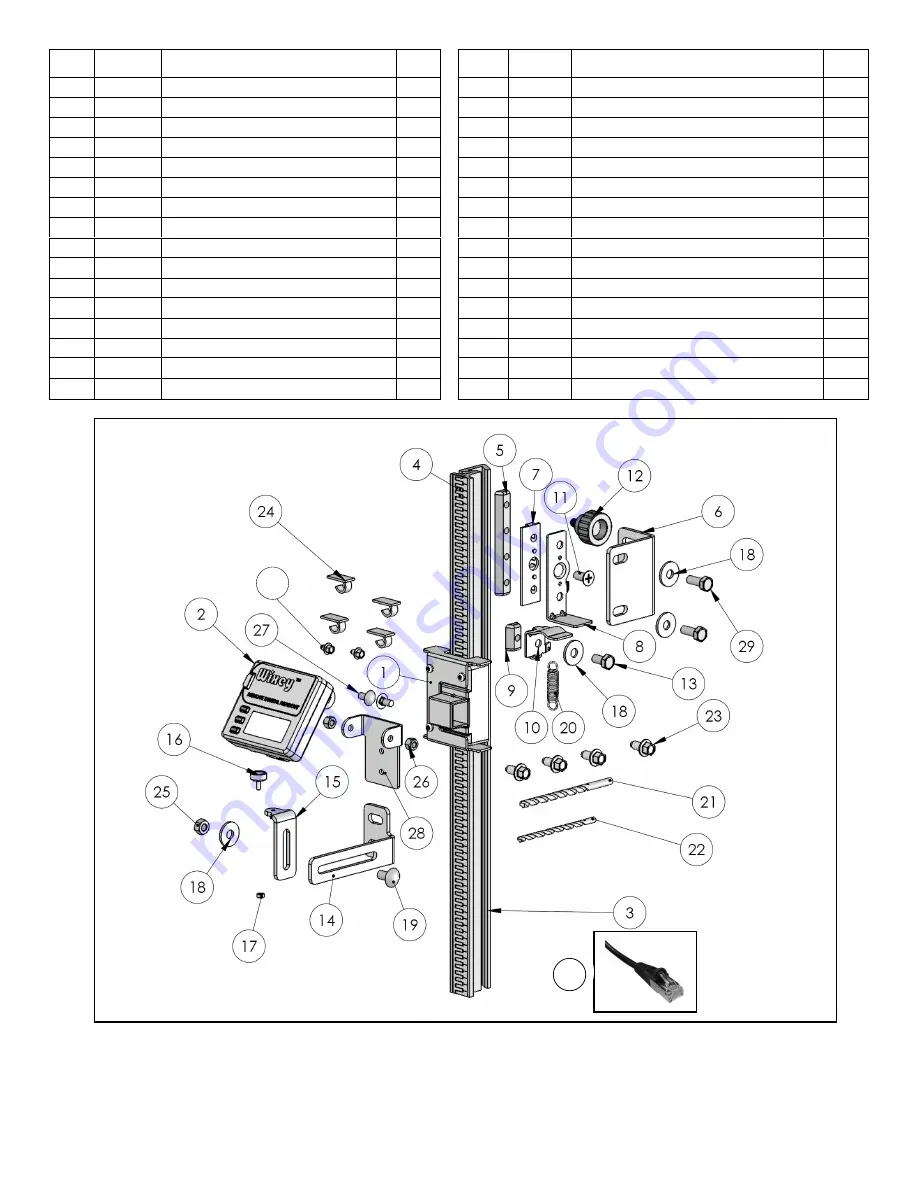

8

For questions, comments, spare parts, and application examples go to: www.wixey.com

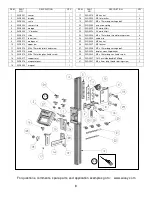

ITEM

PART

NO.

DESCRIPTION

QTY.

ITEM

PART

NO.

DESCRIPTION

QTY.

1

WR5501

sensor

1

17

WR5519

M3 hex nut

1

2

WR5502

display

1

18

WR5520

M6 flat washer

4

3

WR5503

scale

1

19

WR5521

M6 x 12mm long carriage bolt

1

4

WR5504

sensor strip

1

20

WR5506

extension spring

1

5

WR5508

wedge

1

21

WR5522

5.5mm drill bit

1

6

WR5509

"L" bracket

1

22

WR5523

3.6mm drill bit

1

7

WR5510

slide

1

23

WR5524

M6 x 12mm long thread forming screw

4

8

WR5511

lower jaw

1

24

WR5525

cable clip

4

9

WR5512

wedge nut

1

25

WR5526

M6 hex nut

1

10

WR5513

upper jaw

1

26

WR5527

M5 lock nut

2

11

WR5514

M6 x 10mm long flat head screw

1

27

WR5528

M5 x 12mm long carriage bolt

2

12

WR5515

knob

1

28

WR5529

display mounting bracket

2

13

WR5516

M6 x 12mm long hex head screw

1

29

WR5530

M6 x 16mm long hex head screw

2

14

WR5517

support arm

1

30

WR5507

Cat 5e shielded cable 2M long

1

15

WR5518

magnet mount

1

31

WR5531

M4 x 8mm long thread forming screw

2

16

WR5505

magnet

1

31

30