Manual_S5_Airplus_2015_04_20

Page 57 / 68

©

Wodtke GmbH - Tübingen. All Rights and Changes Reserved.Printed 04/2015

Part No. 950 976

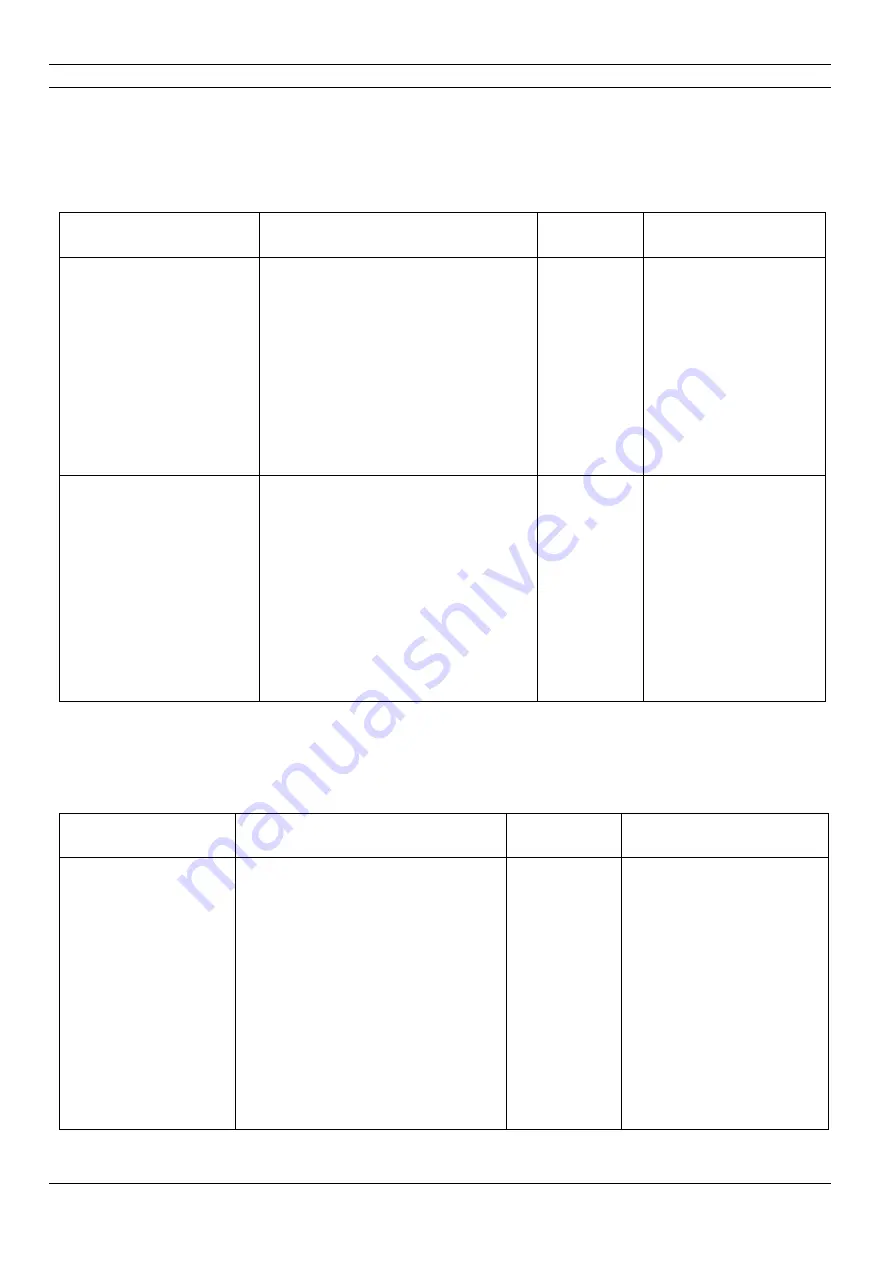

18.2 Overview of Class 2 Error & Fault Codes (Not Safety-Related)

Class 2 errors are of subordinate importance (not safety-related) and manual reset is not required

after resolving the cause of the fault. The automatically returns to normal operation after resolving

the cause of the fault.

Fault code

Class 2

Cause of fault

Target values

Resolution of fault

L- LO =

Air volume in intake pipe un-

derrun, L-LO indicator blinks in

alternation with the respective

programme indicator.

Measurement point: Air vol-

ume sensor in intake pipe [=

two resistors in bridge circuit,

one

resistor

continuously

heated. Cooling = function of

flow speed]

External error / operating error! Minimum air

volume in intake pipe underrun longer than

5 seconds.

This occurs due to opening of the combus-

tion chamber doors, for example

no air

through-put through the intake pipe

Another cause: if the air through-put through

the unit is no longer possible due to extreme

contamination of the heating gas flues / con-

nector or the resistance in the combustion

line is too high or the combustion air line is

closed/clogged.

L

>

2.0

Value is que-

ried continually

starting 1 mi-

nute after start.

After a restart,

the query also

does not hap-

pen until after

1 minute.

There is not a unit defect!

Close combustion chamber

door (if open) or find other

cause (e.g. access panel

open, door not sealed). Per-

form maintenance/cleaning

as required. Unit continues

to operated in the previous

programme after error is re-

solved.

Exception: Flue gas tem-

perature has dropped. Then

the indicator "TR" appears

see Cl. 1 error code

BU Er1 =

BUS error (RS 485 - interface)

BUS error on input "RS 485" with normal

shutdown HE OFF / G OFF / BU ER1. Bus

communication with external heating con-

troller disrupted for longer than 60 seconds

or external heating controller/gateway incor-

rectly connected/defective or RS 485 input

defective.

Error can only occur if the "BUS" input is

switched active (activation / deactivation via

menu level 2 - see Chapter 8.3.3).

Inspect BUS cabling (conti-

nuity, polarity, installation)

to

the

external

gate-

way/controller. Error is reset

automatically + furnace re-

started as soon as the BUS

connection is active again.

Attention:

with "BU Er1,"

the furnace can only be

manually operated if the

"BUS" input is deactivated

(activation / deactivation via

menu level 2 - see Chapter

8.3.3).

18.3 Internal Regulation Function "R.M"

This function is summarised here because it partially also serves for technical safety monitoring of the units and is

significantly influenced by external parameters. These are regulation functions - the units respond to external influ-

ences / operating parameters here.

Regulation function / dis-

play indicator

Cause

Target values

Resolution of fault

R.M =

Internal modulation

No error in an actual sense

(regulation function)

Case A:

Value for flue gas temperature TR

was exceeded, the unit switches back to

lowest load until the values are met. This is

a regulation function (not a defect), which

can be triggered by operating with pellets

with a high heating value (average output

of the unit is over the rated heating output

as a result).

Case B:

The temperature on the air volume

sensor was exceeded. The furnace regu-

lates to the lowest output. Once the tem-

perature lowers sufficiently, the furnace re-

turns to the previously adjusted output.

This is a regulation function (not a defect)

which can be triggered by the combustion

air temperature being too high, for exam-

ple.

TR

max

< 999 °C

with hysteresis

6 C

T

L

< 90 °C

There is an automatic return

from modulation "R.M" to the

preset output as soon as the de-

vice values have lowered by the

cited hysteresis.