Data sheet

P0688.10.13 EN

Replaces

P0688.07.13 EN

Page 1 of 7

Data sheet

P0688 EN

Page 2 of 7

Progressive distributor

WOERNER

In progressive mode based central lubri-

cation systems

The main features of

progressive distributors are as follows

Clear and precise arrangement of

control channels in

Quick fault remedy possible without

having to loosen the pipeline

selectable in accordance with the

lubricant required

due to

refined sliding surfaces

can be replaced during operation

Proportioning volume

per cycle

Lubrication point

connections at max.

Operating pressure at

Throughput volume in case of

Material

Proportioning block

Internal parts

Connecting plate

Delivery medium

Mounting position

usually as needed

Note: In case of heavy vibration or

shock load, install the distributor such

that piston axes are situated vertically to

the main direction of shock impact.

An optimum ventilation of the whole

lubrication system is the precondition

for its functionally safe operation.

For quicker ventilation, the flow direc-

tion from bottom to top in the distributor

is of advantage (inlet on bottom side).

The distributor must not be "distorted".

Therefore, when mounting it, always be

careful that the supporting surface is

level.

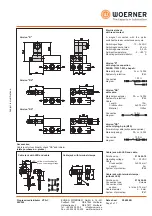

VPA-C

Use:

Technical data:

:

:

0,1 ... 0,9 cm³

:

20

max.:

150 bar

Oil at max.:

2500 cm³/min

Grease at max.:

250 cm³/min

:

Aluminium

:

Steel

:

Aluminium

Temperature range:

-20 ...

on request

0,05 cm³

Oil-viscosity:

>6 cP

Grease:

up to NLGI category 2

+80 °C

:

+

+

+

+

+

+

Accurate proportioning volumes

Modular system construction

9 different proportioning volumes

Extremely long service life

Pluggable monitoring elements

spite of small-size

construction

+

No proportioning decrease at the

piston monitored

Progressive distributor VPA-C

205.000

Progressive distributor VPA-C

205.000

A1=

A2=

B =

)

D =

DPA-C

H = Main line

K =

M = 2x

(see data sheets P0683)

R =

APA-C

S =

Mounting position at the distributor (for

visual indication and electrical checking

device) at first place

Mounting position at the distributor (for

electrical checking device) at last place

Mounting point for viewing indicator at

distributor (if point A is occupied

Proportioning block

Proportioning volume distinctive number

M8 fastening threads for assembly

of auxiliary units

Connecting plate

Mid fastening screw

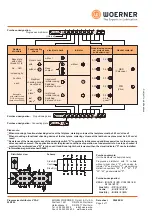

130

1,30

6

152

1,65

8

174

2,00

10

202

2,30

12

224

2,60

14

246

2,90

16

268

3,25

18

290

3,60

20

Length

"a"

Weight

kg

Number

of outlets

-

-

-

92

114

114

136

136

Length

"s"

Casing for initiator

Visual check "S"

Functional checks

Visual check "S"

In a translucent polyamide casing, a red pin

being fixed to the piston shows the piston's

movement.

Casing material:

Polyamide, translucent

Ambient temperature:

-10 ... +80 °C

Weight:

0,35 kg

Mounting point at distributor:

A or B

:

:

Electrical check with initiator:

Casing for initiator:

A pin being connected with the piston

attenuates an initiator once per cycle.

Version "D":

Casing material:

Polyamide, translucent

(Piston movement is visible)

for initiators with a

switching distance of:

8 mm

Version "W":

Casing material:

Polyamide, black

for initiators with a

switching distance of:

5 mm

Use initiator with M18x1 thread!

(When using other initiators than those

depicted below, such initiators must be

checked for suitability.)

³

³

Choice of initiators:

Operating voltage:

Connection diagram:

Dimension drawing:

Initiator "C"

913.900-03

10 ... 30 VDC

Residual ripple:

£

10%

Load current at max.:

250 mA

Protection system:

IP67

Power connection:

Cable 3 m

Unit plug (

3)

see accessoires page

Length "A":

76,5 mm

Designation /

Purchase-no.

10 ... 30 VDC

£

15%

130 mA

IP67

45 mm

Initiator "N"

913.900-21

Switching

:

distance

8 mm

8 mm

G 1/4

1)

1)

Base plates threaded G 1/8

see data sheet S0688

-Subjecttomodifications-

-Subjecttomodifications-

EUGEN WOERNER

GmbH & Co. KG

Postfach 1661

DE-97866 Wertheim

Hafenstrasse 2

DE-97877 Wertheim

Tel. +49 9342 803-0

Fax. +49 9342 803-202

www.woerner.de

info@woerner.de

EUGEN WOERNER

GmbH & Co. KG

Postfach 1661

DE-97866 Wertheim

Hafenstrasse 2

DE-97877 Wertheim

Tel. +49 9342 803-0

Fax. +49 9342 803-202

www.woerner.de

info@woerner.de