Data sheet

P0688 EN

Page 6 of 7

Data sheet

P0688 EN

Page 5 of 7

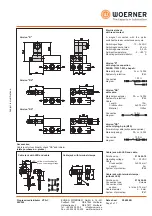

I

II

III

1

2

3

4

5

6

Left-side

bypassline

Right-side

line

bypass

Mainline

Fig. 1

II

II

1

2

3

4

5

6

Fig. 3

I

1

2

3

4

5

6

Fig. 2

III

1

2

3

4

5

6

Fig. 4

Monitoring of

progressive distributors

As for instance due to soiling, the flow

through a lubricant point line may be

prevented. This will cause a piston to get

blocked. By virtue of the forced control as

depicted in figures 1 up to 4, the other

pistons will be stopped as well.

Due to this configuration, the proportioning

at all outlets of the distributor can be

monitored by means of a sensor at one

piston only.

Mounting note:

The pistons are provided with an extremely

small fitting clearance. Therefore, the pis-

tons, after the dismantling of a distributor,

must never be interchanged.

Distinctive letters

ouble bridge without

check valve

riple bridge without

check valve

utlet at the bridge

without check valve

opposing outlets

separated

opposing outlets

connected

open outlet

ock screw

:

B = D

P = T

A = O

Z =

K =

0 =

V = L

Setting of the initiator:

1. Switching on the pump (distributor

circulates).

2. Screwing the initiator completely in. In

the case of a permanent signal, turning

back the initiator as far as an alternating

signal occurs.

3. Turning back the initiator until no signal is

released.

4. Setting the initiator between the limit

values

2 (alternating)

and

3 (no

signal)

5. Secure the initiator with a counter nut.

"

"

"

".

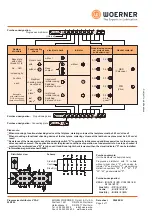

Progressive distributor VPA-C

205.000

Progressive distributor VPA-C

205.000

Combination of outlets,

doubling the proportioning volume at an outlet:

Connect opposing outlets by removing the "Z" screw.

Close any of the outlets by means of a screwed sealing plug

Without removal of the "Z" screw, no outlet must be locked.

.

Z

2 adjacent outlets are combined into

one outlet by means of a double

bridge.

Add-on elements and combination of outlets:

5 outlets are combined into one outlet

by means of a triple bridge, a double

bridge, and removal of the "Z" screws.

Open outlets

2 opposing outlets are combined by

removing the "Z" screws.

Side A (R)

Centre

Side B (L)

Accessories

Pipe screw fittings

:

DIN 2353 and lock screw:

.

(

)

please state purchase-no.

Only in conjunction with progressive distributor. For spare parts see spare part list E0117

Bridges:

(please state purchase-no.)

double without

outlet (B-B)

triple without

outlet (P-P-P)

double with

outlet (B-A)

triple with

outlet (P-P-A)

752.205-90

752.205-91

752.205-92

752.205-93

Bridges

double without

outlet (B-B)

triple without

outlet (P-P-P)

double with

outlet (B-A)

triple with

outlet (P-P-A)

752.205-94

752.205-95

752.205-96

752.205-97

Bridges

(

"S")

location of the mid fastening screw

For mid fastening screw "S" position

–

–

752.205-98

752.205-99

–

–

752.205-A0

752.205-A1

without

with

Check valve

at the outlet

1)

Outlet at max ø10

Connection

thread

G 1/4

951.100-51

951.100-12

951.100-14

951.100-17

6

8

10

12

Pipe screw fitting with pipe outer diameterø

1)

206.674-65

Check valve with pipe outer diameterø

501.152-65

501.151-65

501.153-65

6

8

10

Lock screw

"V"

Functional process fig. 1 ... 4:

The lubricant flows from the main line

through the right-side ring groove of piston

III as well as the bypass line (right) and to

the left side of piston I and moves it into its

home position. The lubricant displaced by

piston I is ejected via the left bypass line

through outlet no. 6

After shifting of piston I, lubricant flows to

the left side of piston II and pushes it into its

right-side home position. The displaced

lubricant is ejected via outlet no. 1

After shifting of piston II, lubricant flows to

the left side of piston III and pushes it into its

right-side home position. The displaced

lubricant is ejected via outlet no. 2

After shifting of piston III, lubricant flows to

the right side of piston I and pushes it into its

left-side home position. The displaced

lubricant is ejected via outlet no. 3. The

continuation of that process is evidenced in

the scheme depicted

.

.

.

.

Formula for calculating the lubricant

available per lubrication point:

A progressive distributor allocates the

delivered lubricant to the individual lubri-

cation points in forced order. Due to the

functional process as described herein, a

safe proportioning is ensured

The lubricant

delivered to a lubrication

point i can be calculated as follows

lubricant delivered to the distributor

.

Q =

,

K =

i

i

distinctive number of the outlet

q

i

q =

Q

i

¾¾¾¾¾¾¾¾ *

K

i

2 (K +K +K ...)

*

1

2

3

-Subjecttomodifications-

-Subjecttomodifications-

EUGEN WOERNER

GmbH & Co. KG

Postfach 1661

DE-97866 Wertheim

Hafenstrasse 2

DE-97877 Wertheim

Tel. +49 9342 803-0

Fax. +49 9342 803-202

www.woerner.de

info@woerner.de

EUGEN WOERNER

GmbH & Co. KG

Postfach 1661

DE-97866 Wertheim

Hafenstrasse 2

DE-97877 Wertheim

Tel. +49 9342 803-0

Fax. +49 9342 803-202

www.woerner.de

info@woerner.de