Wogaard Coolant Saver

TM

Manual

Version 1.2-Eng

Page

12

of

19

6.

The 12 mm PU hose is inserted at the end of the venturi-unit pointing towards the ground.

The hose should be cut to length with a utility knife, so the end of the hose is approx an

inch above highest possible water-level.

Caution:

Avoid bending the 12mm hose. Please ensure that the hose is mounted in a way

that prevents it from shifting position, as a result of changes in flow. You should drill a 12.5

- 14 mm hole in the top plate of the coolant reservoir to accommodate the 12mm PU hose.

If you feel uncomfortable doing this, you can alternatively fix the hose in an appropriate

manner using regular cable ties. THE HOSE MUST NOT TWIST OR BEND SHARPLY! If the

liquid cannot flow through the hose, it will come out of the vacuum cup!

7.

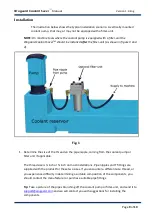

Place the vacuum cup on the bottom surface of the chip container. One end of a 6mm PU

hose is attached to the vacuum cup. The other must be inserted into the side port on the

venturi-unity and the thumb-screw is tightened (see fig. 4 below).

Fig. 4

8.

Connect the hose supplying coolant or cutting oil to the machine, to the end of the T fitting

as shown in Fig. 3 and Fig. 4.