Wogaard Coolant Saver

TM

Manual

Version 1.2-Eng

Page

5

of

19

Employer obligations:

The employer is obliged to ensure that only people, who meet the following

conditions, may use the equipment.

People who:

1.

Have had proper instructions on the use of the equipment.

2.

Have read these basic safety precautions.

Warning!

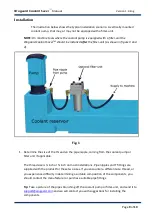

Always turn off the machine driving the coolant pump, when installing the

equipment.

When the equipment is installed you can shut off the ball valve and remove the

venturi-unit, by unscrewing it from the ball valve. This allows for cleaning or

inspection, if necessary, without interrupting the machine operation.

Warning!

Do not try to separate the unit from the machine piping during operation if the unit

is installed in a cramped space, where it may be difficult to move the hand-tools

freely.

If you suspect the equipment to be faulty, shut off the ball valve immediately and

contact the manufacturer to resolve the issue.

Residual risk

In spite of all safety measures, personal safety equipment and optimum organization

safety procedures, it is not possible to rule out damages to other equipment or even

personal injury.

Should an accident occur, you must inform the manufacturer. The manufacturer has

an obligation to monitor the products, in order to take appropriate action, through

the ongoing product development, to prevent or eliminate all risk elements

associated with this equipment.