17

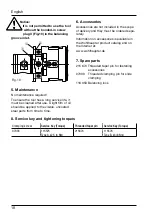

Notice:

Do not make any diameter

adjustments in the clamped

state! The adjustment parts

could be damaged otherwise.

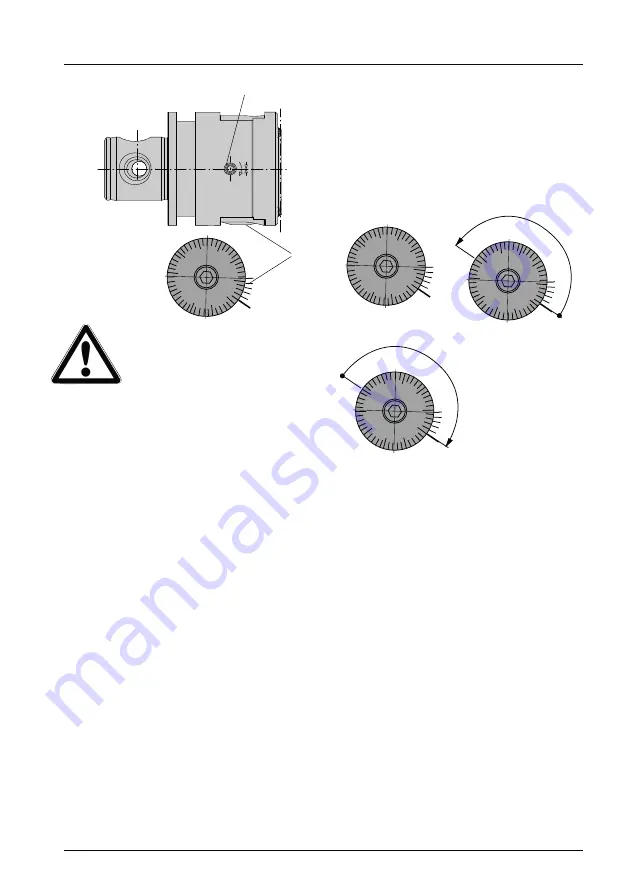

Diameter adjustment

(Fig. 9)

Please observe sequence:

1. Release threaded clamping pin

1

2. Turn scale

2

to adjust tool diameter.

• On tool presetting device

• On machine using gage cut or trial

drill

• 1 turn of scale: 0.5 mm (.020“)

adjustment in Ø

• 1 scale mark: 0.01 mm (.001“)

adjustment in Ø

• 1 vernier scale mark: 0.002 mm

(.001“) adjustment in Ø

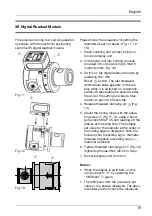

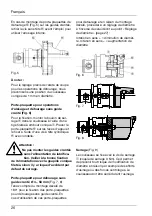

2.1 Readjust tool (increase Ø) readjust scale

to required value

or

2.2 Reset tool

• Determine value set on tool (Fig a,

scale value 21)

• Turn scale back by one half-turn, left

direction of rotation (Fig. b)

• Set new (smaller) scale value

3. Tighten threaded clamping pin, tighte-

ning torque 3 Nm (Fig. c, scale value 20)

The path of the slider is restricted. Any att-

empts to adjust against the end stop may

damage the tool.

20

30

10

0

40

10

15

5

0

a)

20

30

10

0

40

10

5

0

15

b)

Example:

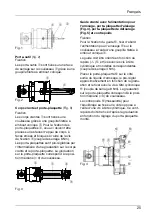

Balancing

(Fig. 10)

The tool is equipped with a groove for

inserting balancing weights

1

.

Precision balancing is performed using up

to 6 balancing weights and a pre-balanced

basic support with a balancing machine.

Markings

2

on the tool mean that neutral

positions for the four balancing weights can

be set time and time again.

To install the balancing weights, insert the

screw plug

3

into the T-shaped groove

first. Finally, apply coating of Loctite 234 to

screw plug, screw all the way in and then

tighten (tightening torque 8 Nm (70.81 in.

lbs.))

Fig. 9

2

20

30

10

0

40

10

15

5

0

20

30

10

0

40

10

15

5

0

c)

English

1

Summary of Contents for VARIOBORE 536

Page 1: ......