53

W415-1600 / 06.01.16

DAMAGE

VACUUM

SWITCH

-

The vacuum switch wire

connections are bad.

-

Vacuum switch has failed

(very rare).

-

Check the connections

-

To test, you will need to disconnect the vacuum switch

and very gently suck on the loose end of the hose. If you

hear a click, the vacuum switch is working. Check air hose

for blockage.

CAUTION: TOO MUCH VACUUM CAN

DAMAGE THE VACUUM SWITCH.

-

Other restoration operations must be carried out by an

authorized technician.

COMMAND

AUGER ALARM

-

The auger shaft is jammed.

-

The auger motor has failed.

-

Defective auger motor.

-

Abnormal functioning of pellet

feeding.

-

Start by disconnecting the power supply and emptying the

hopper.

-

The auger shaft may be jammed.

-

Remove the auger motor from the auger shaft and try to

run the appliance. If the motor will turn, the shaft is jammed

on something. If the motor will not turn, the motor is

defective.

-

Other restoration operations must be carried out by an

authorized technician.

PELLET HOPPER

OPEN

-

The hopper lid is open or not

properly closed.

-

The appliance switched off

since the hopper lid was open

or not properly closed.

-

Close the hopper lid within 30 minutes of this alarm.

-

Ensure that the hopper lid is properly closed and restart the

appliance.

DISPLAY

SYMPTOM

TEST SOLUTION

SOOT ACCUMULATES ON GLASS AT A FAST RATE -

FLAME IS LAZY, DARK AND HAS

BLACK TIPS, THE BURNPOT OVERFILLS

-

-

Appliance or vent pipe is dirty,

which restricts airflow through

the burnpot

-

Follow all cleaning procedures in the maintenance section

of the manual.

-

-

Vent pipe is installed

improperly.

-

Refer to the “VENTING” section in the manual to determine

where the venting system is installed incorrectly.

-

-

Burnpot holes are blocked.

-

Remove the burnpot and thoroughly clean it.

-

-

Blockage in air intake pipe

-

Visually inspect the air intake pipe that leads into the

burnpot for foreign material

-

-

Circuit board malfunction

-

Time the fuel feed light at each setting (after the appliance

has completed the start-up cycle). If auger motor runs

constantly, the board is defective.

-

-

Poor quality pellets

-

The brand of pellets or batch of pellets that are being used

may be of poor quality. If possible, try a different brand of

pellets. You might also want to try a brand that is made

from a different type of wood (softwood vs. hardwood).

Different woods have different characteristics when being

burned.

-

-

The pellet feed adjustment is

too high.

-

See “PELLET FEED ADJUSTMENT” section.

SMOKE SMELL IS COMING BACK INTO THE HOME

-

-

There is a leak in the vent

pipe system

-

Inspect all the vent pipe connections. Make sure they are

sealed with RTV silicone that has a temperature rating of

260°C (500°F) or higher. Seal joints with UL-181-AP foil

tape and insure the square to round adapter piece on the

combustion blower has been properly sealed with the same

RTV.

-

-

The gasket on the

combustion blower has

deteriorated.

-

Inspect both gaskets on the combustion blower to make

sure they are in good shape. Replace if necessary.

VERY ACTIVE FLAME ON PILOT (P-1)

-

-

Flame is very aggressive on

low feed setting, consumption

of pellets seem to be high.

-

Restoration operations must be carried out by an

authorized technician.

NOTE : The following symptoms may occur without a designated display appearing. Continue troubleshooting as outlined

below or contact your purchase dealer.

Summary of Contents for Vicenza V5.2

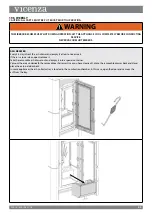

Page 15: ...SECURING kit FIGURE 2 15 W415 1600 06 01 16...

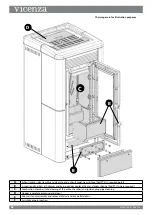

Page 26: ...TRIVET 7 REPLACE TRIVET 26 W415 1600 06 01 16...

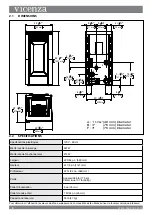

Page 56: ...57 W415 1600 06 01 16 24 0 NOTES 44 1...

Page 57: ...58 W415 1600 06 01 16 44 1...

Page 72: ...14 W415 1600 06 01 16 KIT DE FIXATION FIGURE 2...

Page 83: ...25 W415 1600 06 01 16 GRILLE REMPLACER LA GRILLE...