20

3064058_201610

AHU TE

AHUW TE

Installation instructions

When installing the scrubber take care not to permit dirt or other foreign matter to enter

the scrubber, as otherwise the pump impeller will be obstructed and this will either

significantly impair pump operation or result in its destruction.

Given normal requirements, the water for the scrubber must comply at least with the

minimum quality specified below:

Appearance

clear, colourless, no sediment

pH value

7 to 8.5

Total salt content

< 800 g/m

3

Electr. conductivity

< 100 mS/m (at 20 °C)

Calcium ion content

> 0.5 mol/m

3

Carbonate hardness

< 4.0 °d

Carbonate hardness with

hardness stabilizers

< 20 °d

Chloride content

< 180 g/m

3

Sulphate content

< 290 g/m

3

KMnO

4

consumption

< 50 g/m

3

Germination index

< 1000 ml-1

If the scrubber is connected to the mains water system, ensure compliance with DIN

1988 [or local regulations].

Note

Scrubber section

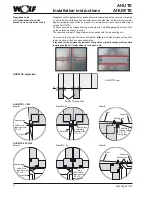

If the siphon is provided on site, calculate the height of the siphon in accordance with

the sketch shown here.

The effective siphon height H (mm) must be greater than the max. negative or positive

pressure (in Pa) inside the air-handling unit (1 mm WS = 10 Pa).

The difference in height between the unit outlet and the siphon overflow should also

be equal to H (in mm).

Double siphon

(on site)

Ball siphon

h

Never connect the siphon discharge directly to the wastewater system. Instead, leave

the end of the discharge open so that it can drain freely. Long discharge lines must be

vented to prevent condensate from backing up in the pipe (provide an additional opening

in the siphon discharge pipe).

To permit reliable draining of condensate, it is important to connect a ball siphon to the

condensate drain connector from the drain tray for the cooling coil / direct-expansion

evaporator, plate-type heat exchanger and outside air intake tray of the AHUW TE.

Also observe that each condensate drain connector must have a siphon connected to it.

It is not permissible to run two or more condensate drain connectors into a shared siphon.

The ball siphon is self-filling. A floating ball prevents air being inducted when the system

is dry, which means that condensate initially has to fill the siphon as it is produced. The

ball also acts as a non-return valve and prevents the siphon from sucking dry.

It is very important to ensure that the

foundation is of adequate height

to permit

installation of the siphon.

The effective siphon height H (mm) must be greater than the max. negative or positive

pressure at the condensate connector (1 mm WS = 10 Pa).

H = 1.5 x p (mm water column) + 50 mm (min.)

p =

Negative or positive pressure in mm of water column as per appliance design

50 mm (water column)

= Reserve (to allow for design inaccuracies, evaporation)

1.5

= Additional safety factor