30

3064058_201610

AHU TE

AHUW TE

Maintenance

Dampers

Never oil dampers. Oil could damage the plastic used. In that case the damper function

would no longer be ensured.

Blow the dampers clean with compressed air; no other maintenance is required.

Heat exchanger

(heating coil / cooling coil / KGX)

Check periodically for contamination and clean as necessary.

Clean the heat exchanger by:

- Vacuum extraction

- Blowing down with compressed air

- Spraying with water or steam

Ensure that the air/water/steam pressure for cleaning is not in excess of 5 bar, otherwise

there is a risk of mechanical damage to components.

Check the condensate drain.

Open the siphon, clean it and refill it.

Use a commercially available descaling agent to clean the drop-eliminator sections.

Note

Scrubber

Regularly clean the scrubber and the mist eliminator. Cleaning intervals are subject to

operating method, air condition and water quality.

Maintenance involves draining the tray and rinsing it with clean water or a high pressure

cleaner.

Spray pipework and nozzle assembly only with reduced water pressure.

Parts could be damaged by a jet of water at excessive pressure.

Commercially available descaling agents can be used.

Never use foaming cleansers.

The scrubber pump is maintenance free.

However, when cleaning the scrubber it is advisable to flush the pump and the pipework

with clean water.

If the scrubber is out of use for a longer period of time, start the pump weekly and allow it

to run for approx. 5 minutes to prevent the bearings from seizing (never run the pump dry).

Note

Note

Filter

Wear protective clothes, protective gloves and a respirator when exchanging the

filter!

Contaminated filters are dangerous to human health. Contact with filter dust can

cause allergic reactions of the skin, eyes and respiratory organs

If filter inserts require cleaning or replacement, open the inspection door

and pull them to the side and out of the casing.

Category G4 synthetic fibre filter mats used as filter inserts can be regenerated. The

mats can be tapped clean, blown clean, vacuum cleaned or washed out in a solution

of commercially available fine detergent and lukewarm water.

Never wring out the

mats.

Bag filters cannot be regenerated. Replace the bag filters when the pressure drop

exceeds the permissible maximum because of clogging.

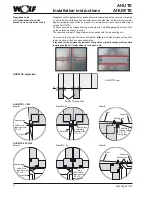

When bag filter inserts require replacement, open the inspection door and release the

quick action clamp, then pull the bag to the side and out of the casing.

(pull quick action clamp with a tool = remove filter;

(push quick action clamp with a tool = filter tensioned)

Note:

Pull the swallow tail seals off the spent filters and push them into position on

the replacement filters. This is important to ensure that the new filters are reinstalled

correctly.

Activated charcoal filter

Replace the activated charcoal filters (cartridges) if they are saturated (expiry of the

specified operating time).

The cartridges are fastened with special bolts (bayonet connection). Rotate the cart-

ridges and pull them towards you out of the frame. When exchanging the activated

charcoal filter cartridges, the pre-filters should also be renewed in order to achieve

optimum service lives of the activated charcoal filters.

Quick- action

clamp

Bag filter

Operator side