WOLF

ATEX

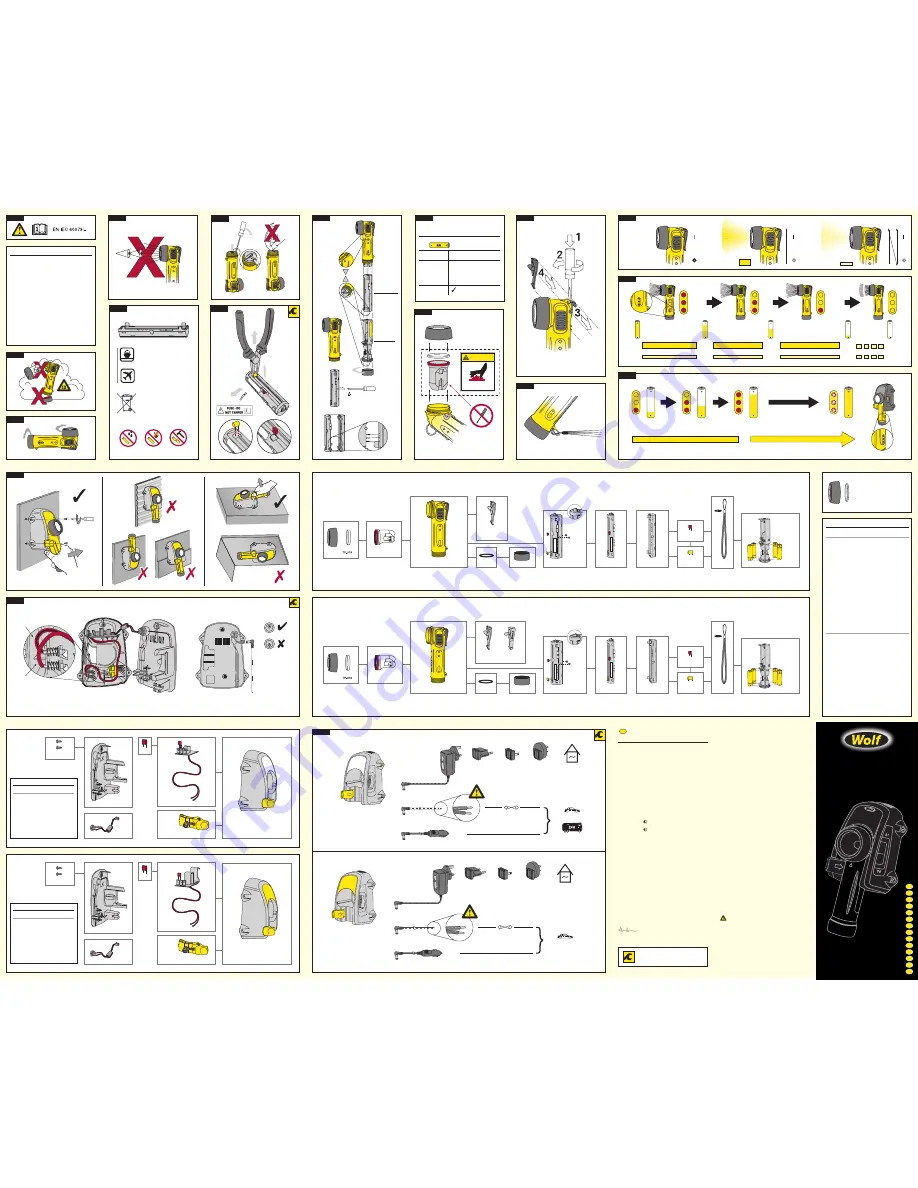

RECHARGEABLE TORCH

OPERATION AND

MAINTENANCE INSTRUCTIONS

ATEX and IECEx Certified for

Explosive Atmospheres

R-50 and R-55

R-221 Zone 1 Halogen

R-221 Zone 1 Halogen

TP-343

TP-260

R-291

TP-448

R-253

R-255

R-451P

R-285

R-275

R-271

R-640P

R-620P

R-488P

R-223 Zone 1 LED

TP-343

TP-260

R-291

R-257

TP-448

R-287

R-243

R-271

R-640P

R-620P

R-488P

TP-311

TP-317

TP-448

R-223 Zone 1 LED

R-393

TP-317

TP-343

TP-260

R-243

R-257

R-287

(Pozi No.1)

R-488P

R-620P

R-640P

R-271

R-291

See Fig. 5

TP-448

R-225 Zone 0 LED

R-393

TP-318

R-337

R-287

R-271

R-243

R-291

R-257

TP-260

(Pozi No.1)

R-488P

R-620P

R-640P

See Fig. 5

R-255

TP-343

R-221 Zone 1 Halogen

R-451P

TP-448

TP-260

R-271

R-285

R-275

R-640P

(Pozi No.1)

R-488P

R-620P

R-291

R-253

See Fig. 5

RC-260

RC-412

RC-438P

RC-240

R-640P

RC-342

RC-450

RC-250

RC-342

RC-438P

R-640P

RC-420

RC-240

RC-450

R-221 Zone 1 Halogen

R-221 Zone 1 Halogen

TP-343

TP-260

R-291

TP-448

R-253

R-255

R-451P

R-285

R-275

R-271

R-640P

R-620P

R-488P

R-223 Zone 1 LED

TP-343

TP-260

R-291

R-257

TP-448

R-287

R-243

R-271

R-640P

R-620P

R-488P

TP-311

TP-317

TP-448

R-223 Zone 1 LED

R-393

TP-317

TP-343

TP-260

R-243

R-257

R-287

(Pozi No.1)

R-488P

R-620P

R-640P

R-271

R-291

See Fig. 5

TP-448

R-225 Zone 0 LED

R-393

TP-318

R-337

R-287

R-271

R-243

R-291

R-257

TP-260

(Pozi No.1)

R-488P

R-620P

R-640P

See Fig. 5

R-255

TP-343

R-221 Zone 1 Halogen

R-451P

TP-448

TP-260

R-271

R-285

R-275

R-640P

(Pozi No.1)

R-488P

R-620P

R-291

R-253

See Fig. 5

RC-260

RC-412

RC-438P

RC-240

R-640P

RC-342

RC-450

RC-250

RC-342

RC-438P

R-640P

RC-420

RC-240

RC-450

RC-200

RC-212

TP-448

R-223 Zone 1 LED

TP-343

TP-282

TP-295

R-243

R-257

R-287

(Pozi No.1)

R-488P

R-620P

R-640P

R-271

R-291

See Fig. 5

TP-448

R-225 Zone 0 LED

R-337

R-287

R-271

R-243

R-291

R-257

TP-260

TP-260

(Pozi No.1)

R-488P

R-620P

R-640P

See Fig. 5

TP-311

TP-282

TP-295

TP-311

R-50

R-55

Parts List

R-50

TP-311 Lens Ring

TP-318 Lens Glass

TP-316 Polycarbonate Lens & Ring Kit Zone 1 & 2

TP-316R Polycarbonate Lens & Ring Kit Red Zone 1 & 2

R-257

Heat Sink LED Assembly

R-223

R-50 Torch Body Assembly Zone 1 &2

TP-343 Clip Moulding Zone 1 & 2

R-287

Cassette Assembly

R-243

Cassette Circuit Half

R-271

Battery Pack

R-488P Lock Screw Cassette (pack of 2)

TP-448 Base ‘O’ Ring

R-291

End Cap Assembly

TP-282 Primary Cell Cassette

TP-295 LR6/AA Primary Cell (pack of 4)

TP-260 Wrist Strap & Ring

R-620P Output Fuse

R-640P Input Fuse (pack of 2)

R-55

TP-311 Lens Ring

TP-318 Lens Glass

R-257

Heat Sink LED Assembly

R-225

R-55 Torch Body Assembly Zone 0

R-337

Clip Moulding Zone 0

R-287

Cassette Assembly

R-243

Cassette Circuit Half

R-271

Battery Pack

R-488P Lock Screw Cassette (pack of 2)

TP-448 Base ‘O’ Ring

R-291

End Cap Assembly

TP-282 Primary Cell Cassette

TP-295 LR6/AA Primary Cell (pack of 4)

TP-260 Wrist Strap & Ring

R-620P Output Fuse

R-640P Input Fuse (pack of 2)

Parts List

RC-200

RC-438P Charger Screw

RC-342 Charger Base Plate

RC-450 Socket and Cable

RC-240 Charger Arm Assembly

R-640P Input Fuse (Pack of 2)

RC-420 Circuit Board

Assembly (RC-200)

RC-250 Charger Body

Assembly (RC-200)

Parts List

RC-212

RC-438P Charger Screw

RC-342 Charger Base Plate

RC-450 Socket and Cable

RC-240 Charger Arm Assembly

R-640P Input Fuse (Pack of 2)

RC-412 Circuit Board

Assembly (RC-212)

RC-260 Charger Body

Assembly (RC-212)

Fig. 1

Pozi No:1

Pozi No:1

Pozi No:1

Fig. 2

Fig. 4

Fig. 5

Li lon

– Less than two batteries

per package

– Less than 100Wh capacity

– Complies with applicable

shipping regulations:

UN

ADR

US CFR 49

IATA

ICAO

IMDG

Fig. 11

Fig. 15

Fig. 14

Fig. 12

Fig. 3

Fig. 8

IECEx Scheme Certification

Cert Number:

IECEx BAS 06.0001X

Models: R-50

Ex ib IIC T4 Gb IP67 / Ex ib IIIB T200

o

C Db

Ex ib I Mb

Temperature Ambient: -40

o

C to 40

o

C

Models: R-55

Ex ia IIC T4 Ga IP67 / Ex ia IIIB T200

o

C Da

Ex ia I Ma

Temperature Ambient: -40

o

C to 40

o

C

IEC Standards Applied:

IEC 60079-0:2011, IEC 60079-11:2011.

Ingress Protection Level:

IP67 to IEC 60529:2001

R-271

Fig. 18

RC-200

12-24V DC

RC-300

Mains Adaptor

Euro

USA

Aus

100-230V AC

254V AC @ 60Hz

RC-452

DC Vehicle Cable

–

+

–

+

RC-454

DC Vehicle Cigarette Cable

2A

12/24V DC

UK

RC-212

12V DC ONLY

RC-300

Mains Adaptor

100-230V AC

254V AC @ 60Hz

RC-452

DC Vehicle Cable

–

+

–

+

RC-454

DC Vehicle Cigarette Cable

2A

12V DC

UK

Euro

USA

Aus

RC-200

12-24V DC

RC-300

Mains Adaptor

Euro

USA

Aus

100-230V AC

254V AC @ 60Hz

RC-452

DC Vehicle Cable

–

+

–

+

RC-454

DC Vehicle Cigarette Cable

2A

12/24V DC

UK

RC-212

12V DC ONLY

RC-300

Mains Adaptor

100-230V AC

254V AC @ 60Hz

RC-452

DC Vehicle Cable

–

+

–

+

RC-454

DC Vehicle Cigarette Cable

2A

12V DC

UK

Euro

USA

Aus

100%

≈

1:00h

≈

2:00h

≈

3:00h

≈

3:30h

50%

3:00h

1:30h

90%

100%

≈

2:00h

≈

4:00h

≈

6:00h

≈

6:30h

Fig. 13

0%

100%

50%

Fig. 6

CAUTION

HOT

Fig. 10

R-50/R-55

Rechargeable

R-287

Primary Cell

TP-282

Wolf Rechargeable Torch Range

Operation and Maintenance Instructions

Please retain – read before use

EC/EU Declaration of Conformity

The R-50 and R-55 meet all relevant provisions of the:-

a) 94/9/EC Explosive Atmospheres (ATEX Equipment) Directive

(up to 19th April 2016)

b) 2014/34/EU Explosive Atmospheres (ATEX Equipment) Directive

(from 20th April 2016)

by virtue of the issued EC/EU type examination certificate, demonstrating

compliance with all relevant harmonised standards and essential health and

safety requirements.

Wolf Rechargeable Torches are self contained safety torches with 3W LED light

sources, moulded in high impact strength plastic and powered by a Lithium Ion

battery pack (optional Primary cell cassette also available). The

R-50 is approved

as Group I, M2 equipment for mining applications, Group II, Category 2 equipment

for use in zone 1 & 2 potentially explosive gases, vapours and mists where the T4

temperature class permits and zone 21 & 22 potentially explosive dusts where the

T200

o

C maximum surface temperature and IIIB dust group permits.

The

R-55 is approved as Group I, M1 equipment for mining applications and

Group II, Category 1 equipment for use in zone 0, 1 & 2 potentially explosive

gases, vapours and mists where the T4 temperature class permits and zone

20, 21 & 22 potentially explosive dusts where the T200

o

C maximum surface

temperature and IIIB dust group permits.

Caution – If fitting Polycarbonate lens, check Ex atmospheres for compatibility.

Approval Codes/Certification:

R-50 Zone 1, 21

I M2/II 2GD Ex ib I Mb/IIC T4 Gb -40

o

C

≤

Ta

≤

40

o

C

Ex ib IIIB T200

o

C Db IP67

R-55 Zone 0, 20

I M1/II 1GD Ex ia I Ma/IIC T4 Ga -40

o

C

≤

Ta

≤

40

o

C

Ex ia IIIB T200

o

C Da IP67

Notified Body:

Baseefa Ltd. Rockhead Business Park,

Staden Lane, Buxton, SK17 9JN, UK.

Notified body number:

1180

EC/EU Type examination certificate:

Baseefa05ATEX0069X

‘X’ condition – Dust layers must be prevented from building up on the torch

and it must not be left energised and unattended in Zone 20 areas.

Harmonised standards applied:

EN 60079-0:2012 +A11:2013, EN 60079-11:2012.

Ingress protection level:

IP67 to EN60529:1992.

The R-50, R-55 with RC-200 or RC-212 is certified compliant with the:-

a) 2004/108/EC EMC Directive (up to 19th April 2016)

b) 2014/30/EU EMC Directive (from 20th April 2016)

To the following harmonised standards BS EN 61000-6-3:2007 +A1: 2011 and

BS EN 61000-6-2:2005 and comply with the requirements of the 2004/104/EC

Automotive EMC Directive for use in motor vehicles to the following harmonised

standards BS EN 50498:2010.

The RC-300 Mains Adaptor is certified compliant with the:-

a) 2004/108/EC EMC Directive and 2006/95/EC Low Voltage Directive

(up to 19th April 2016)

b) 2014/30/EU EMC Directive and 2014/35/EU Low Voltage Directive

(from 20th April 2016)

To the following harmonised EMC standards EN 61204-3:2000 Class B,

EN 55022:2010 +AC:2011 Class B, EN 61000-3-2:2006 +A2:2009,

EN 61000-3-3:2008 and EN 55024:2010 and the following harmonised

LVD standards EN 60950-1:2006 +A2:2013.

Alex Jackson - Managing Director

Wolf Safety Lamp Company Ltd.

Use of the Wolf Rechargeable Torch

A damaged Wolf Rechargeable torch should be repaired in accordance with these

instructions, before putting back into service.

GB

Repairs only to be carried

out by competent persons

PRECAUTIONS: See Figs. 1, 2, 3, 4, 5, 6, 10 & 16

Before use. Charge for 3 hours minimum.

Ensure torch lens ring and end cap are fully tight at all times. (Fig. 3)

Duration in High Power mode

≈

3.5 hours

Duration in Low Power mode

≈

6.5 hours

Deep Discharge Protection: Circuitry will automatically switch the torch off once

the battery reaches a pre-determined low voltage.

The torch must be re-charged before further use.

Emergency Lighting Mode: The emergency lighting function switches the torch

on when a power failure to the charger occurs.

The torch must be placed in the charger switched ‘ON’.

Lamp Replacement: (Fig. 10).

Fuse Replacement: (Figs. 6 & 7).

Cleaning: Use a mild soap and water and soft brush only.

Do not immerse.

Storage: Do not store torch or battery below -20

o

C.

If torch fails to light or;

If indication on charge shows top and bottom indicators only:

A. Ensure torch lens ring and end cap are fully tight at all times (Fig. 3)

B. Place on charge check for indication, remove and switch on.

C. Clean charge rivets, check end cap is fully tightened.

D. Remove cassette (Fig. 6), inspect contacts, test continuity of the fuses,

replace as required (competent personnel only; Fig. 7).

E. Re fit cassette, repeat (A) and switch on.

The R-271 Battery utilises a two cell Lithium Ion system with a life of up to

500 full charge/discharge cycles (to 70% original capacity), and incorporates an

integral encapsulated battery protection circuit.

Replace the

R-271 Battery when the discharge duration is significantly shorter

than the durations shown above.

Recharge every six months in storage.

Battery Information: (Fig. 5), Extraction: (Fig. 6), Connections (Fig. 8).

The TP-282 Primary Cell Cassette. An alternative primary cell cartridge is also

certified safe for use in the torch.

Use only approved primary cells TP-295 for a

T4 temperature class (Fig. 9)

Wolf Chargers: RC-200 (12-24V) and RC-212: (12V) A red LED indicator shows

power to the charger. Charging is fully managed to eliminate battery memory.

Charge is removed once the battery is fully charged, battery voltage is then

monitored; a top-up charge is applied as necessary (typically applying a trickle

charge every 7 days).

Charge Indication: (Fig. 15). Charger Connection Options: (Fig. 18)

– Do not charge in Hazardous Area.

– Charger contacts are low voltage output and short circuit protected.

– Charger operating ambient: +10

o

C to +25

o

C.

– Charger ingress protection IP20, protect from dirt and moisture.

– Do not cover ventilation slots.

Warning RC-452: risk of short circuit if polarity incorrect, (See Fig. 18)

Peak Current (during 3hrs charge period)

=1.5A

Peak Current (standby – fully charged)

=0.08A

Peak Current (no torch in charger)

=0.03A

Output Voltage does not exceed 14V: (Uo=14V)

Warning:

USE ONLY WOLF CHARGERS WITH THESE PRODUCTS (AS SHOWN IN FIG. 18)

USE ONLY WOLF GENUINE REPLACEMENT PARTS.

The Wolf Safety Lamp Co. Ltd has a policy of continuous product improvement.

Changes in design details may be made without prior notice.

–

+

RC-212

12VDC only

RC-452

RC-454

–

+

–

+

2A

12/24VDC

(–) Negative

(+) Positive

Fig. 7

Fig. 16

Fig. 17

GB

F

D

E

I

DK

N

S

NL

P

RUS

J

POL

GR

4x

Wolf part no. TP-295

T Class

T4

LR6/AA

Duracell Industrial,

Alkaline Cells

Duracell Procell,

Duracell Plus,

Energizer Industrial,

Energizer Ultra +

R6 Zinc Cells

Fig. 9

Permitted TP-282 Primary

Cassette Cells

TP-448

R-223 Zone 1 LED

TP-343

TP-282

TP-295

R-243

R-257

R-287

(Pozi No.1)

R-488P

R-620P

R-640P

R-271

R-291

See Fig. 5

TP-448

R-225 Zone 0 LED

R-337

R-287

R-271

R-243

R-291

R-257

TP-260

TP-260

(Pozi No.1)

R-488P

R-620P

R-640P

See Fig. 5

TP-311

TP-282

TP-295

TP-311

TP-316 & TP-316R

Non Glass Applications

R-50 (Zone 1 & 2 only)