67

3061741_201712.indd

CO

2

adjustment

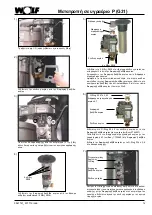

Adjusting the gas:air connection

Carry out the adjustments in the following order: At the factory, the gas combination valve has been adjusted for

the gas type stated on the type plate. Only adjust the gas combination valve after the system has been changed

to a different gas type or when servicing.

If too little heat is drawn off, open some radiator valves.

NB

A) CO

2

adjustment at the upper load (emissions test

mode) for natural gas

- Pivot the control unit flap down.

Unlock the casing cover with the l.h. and r.h. turnbuckles.

Release the bottom of the casing cover and unhook at the

top.

- Remove the screw from the l.h. "Flue gas" test port.

- Insert the test probe of the CO

2

tester into the "Flue gas"

test port (approx. 120 mm).

- Turn the temperature selector to "Emissions test" .

(Illuminated signal ring as status indicator flashes yellow.)

- Ensure that the boiler is not limited electronically.

- Check the CO

2

content at full load, and compare the actual

values with those in the table below.

- Correct the CO

2

adjustment (if required) using the gas flow

adjusting screw on the gas combination valve in accordance

with the table.

Figure: Opening the turnbuckle

l.h. turnbuckle

r.h. turnbuckle

Gas flow adjusting

screw

(only for natural

gas)

Figure: Gas combination valve

- Terminate the emissions test mode by turning the tempera

-

ture selector back into its original position.

- turn clockwise - lowers CO

2

content

- turn anti-clockwise - raises CO

2

content

Figure: Flue gas test with an open boiler

Test port

"Flue gas"

The upper load cannot be adjusted for LPG.

Appliance open

at

upper

load

Natural gas H

8.6% ± 0.2%

LPG P (check)

10.1% ± 0.2%

Summary of Contents for CGB-100

Page 98: ...98 3061741_201712 indd ...

Page 99: ...99 3061741_201712 indd ...