17

3061344_201509

Installation

Gas fittings on the gas burner may be pressure

tested to 150 mbar. Higher pressure may dama

-

ge the gas burner fitting, resulting in a risk of

explosion, asphyxiation or poisoning.

Close the gas shut-off valve on the gas fired

boiler to pressure test the gas pipe.

Mount the gas ball valve in an easily accessible

place.

Connection of a 200 litre Wolf DHW cylinder or third

party cylinder

Connect the DHW flow and return with a three-way diverter

valve or the return of the gas fired boiler. Use a DHW sensor

from the Wolf accessory range when connecting a DHW cy-

linder made by third parties. A detailed description is included

with the connection set (accessories).

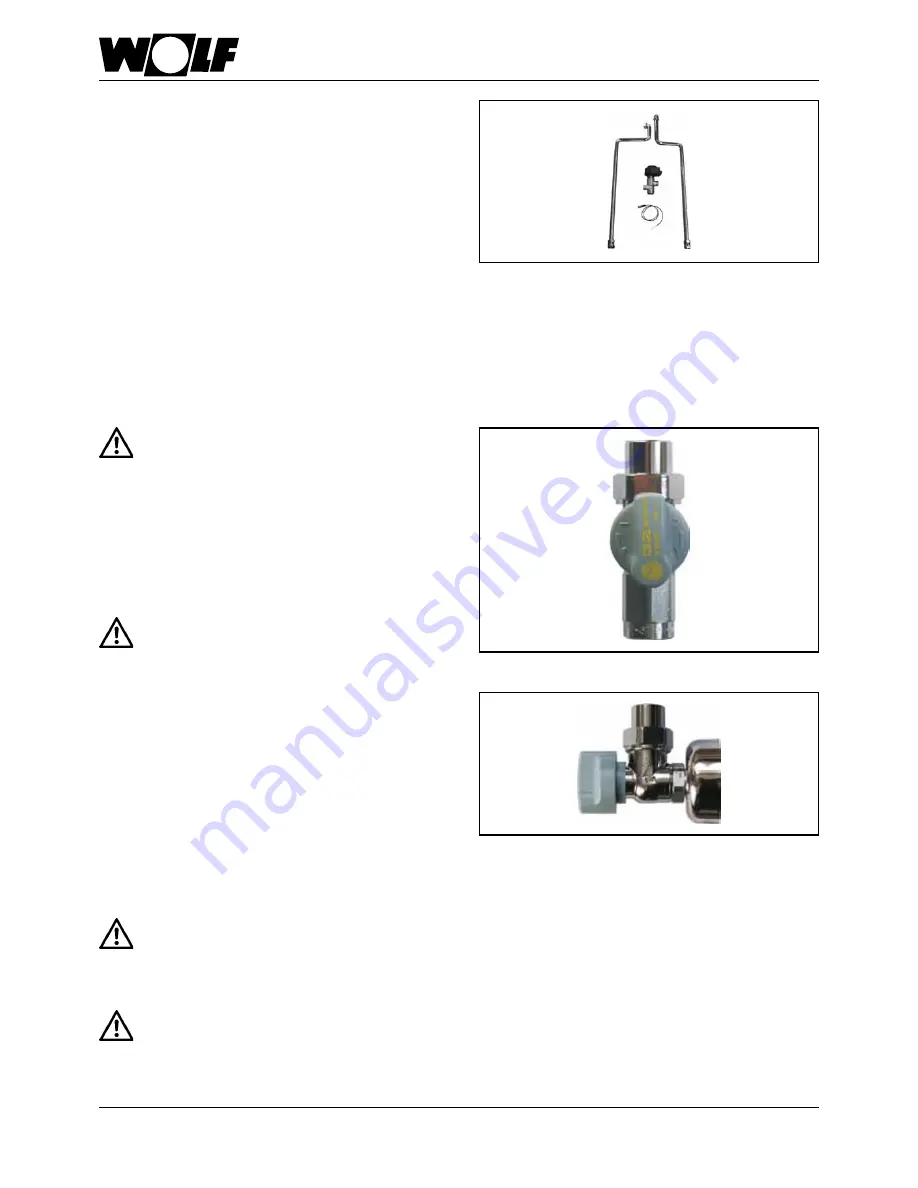

Fig.: Connection set for Wolf cylinder, 200 l, solar buffer

SEM or third party cylinder (accessories)

Gas connection

Laying the gas pipe as well as gas connections

must only be carried out by a licensed gas fitter.

Close the gas shut-off valve on the gas fired boiler

to pressure test the gas pipe.

Clean all residues from the heating pipework and the

gas pipe prior to connecting the boiler, particularly

in older systems.

Prior to commissioning, test all pipe and other gas

connections for soundness.

Inappropriate installation or using unsuitable com-

ponents or assemblies may lead to gas escaping,

which results in a risk of poisoning and explosion.

Install a gas shut-off valve with fire protection in

the gas supply line upstream of the Wolf gas fired

boiler. Otherwise explosions may occur during a fire.

Size the gas supply line in accordance with current

regulations.

Fig.:

Gas shut-off valve straight version (accessories)

Fig.:

Gas shut-off valve angled version (accessories)