62

3062347_0309

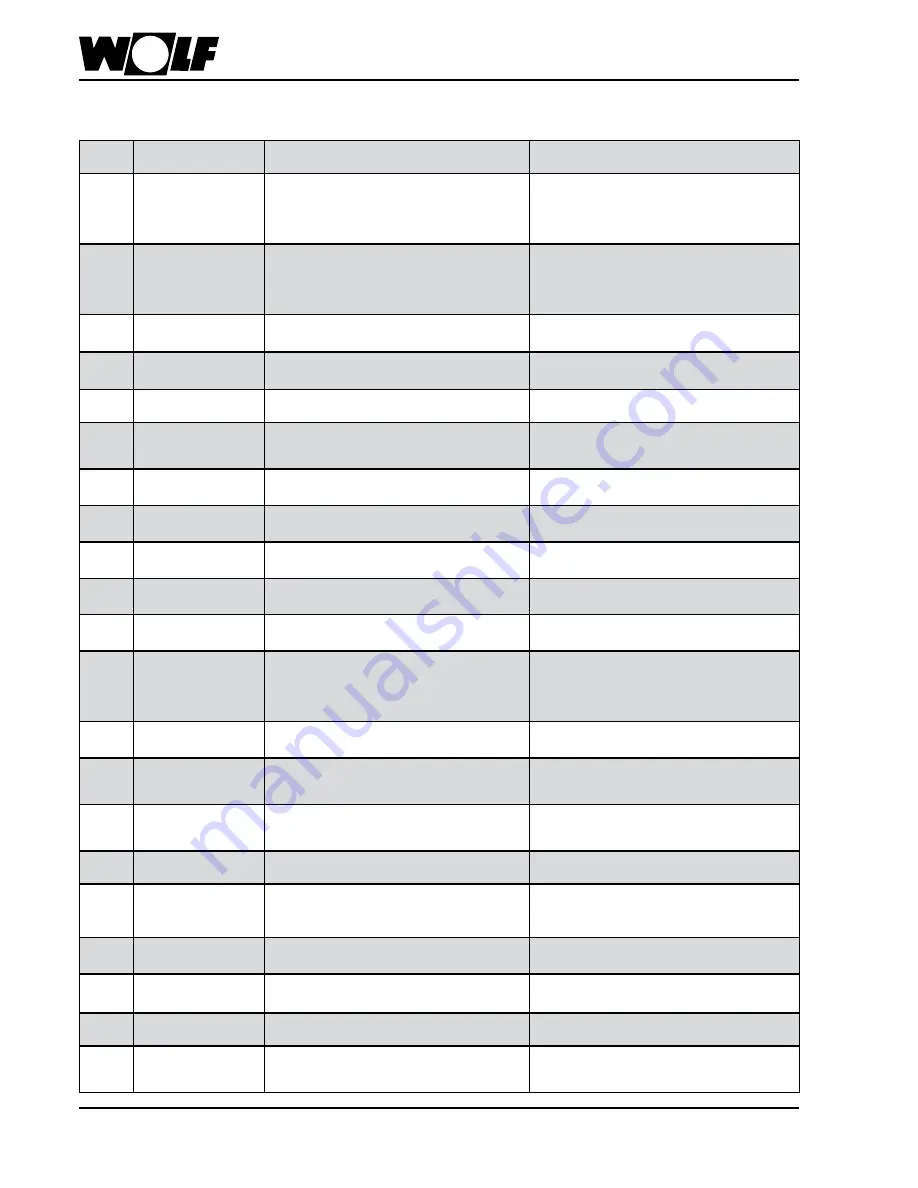

Troubleshooting

Any faults will be displayed as fault code by Wolf controllers with eBUS capability. To these faults, cause and remedy may be

allocated using the following table. This table is designed to allow your local heating contractor to trace the fault more easily.

Fault

code

Fault

Cause

Remedy

1

TBV excess

temperature

The flow temperature has exceeded the limit for

the TBV shutdown temperature.

Heat exchanger severely contaminated.

Check the system pressure. Check the heating

circuit pump. Check the HC pump step switch.

Vent the heating system. Press reset button.

Clean the heat exchanger.

4

No flame established

No flame established during the burner start.

Check the gas supply line and open the gas valve,

if necessary.

Check the ignition electrode and ignition cable.

Press the reset button.

5

Flame failure during

operation

Flame failure during

flame stabilisation or soft start.

Check CO2 Values. Check ionisation electrode and

cable.

6

TW excess temperature The flow/return temperature has exceeded the

limit for the TW shut-down temperature.

Check the system pressure. Vent the system.

Set the pump to stage 2 or 3.

7

TBA excess

temperature

Maximum flue gas temperature exceeded.

Clean burner, check gas pressures

8

Flue gas damper does

not activate

Flue gas damper or its feedback faulty.

Check lead.

Replace flue gas damper.

Check bridges in junction box.

10

Flow sensor 2 faulty

Sensor 2 for the flow temperature or

the lead is faulty.

Check lead.

Check/replace flow temperature 2.

11

Flame pretence

A flame is recognised before the

burner starts.

Check the ionisation.

Press the reset button.

12

Flow sensor 1 faulty

Sensor 1 for the flow temperature or

the lead is faulty.

Check lead.

Check/replace flow temperature 1.

14

Cylinder sensor faulty

DHW temperature sensor or lead faulty.

Check lead.

Check/replace cylinder sensor.

15

Outside temperature

sensor faulty

The sensor for the outside temperature or

the lead is faulty.

Check lead.

Check/replace outside temperature sensor

22

Lack of air

Differential pressure switch will not switch ON.

Press the reset button; check the silicone hoses

to the differential pressure switch. Check flue gas

system and gas fan.

Check the differential pressure switch.

23

Fault differential

pressure switch

Differential pressure switch does not switch OFF.

Press reset button;

replace the differential pressure switch, if required.

25

Gas fan fault

The gas fan does not reach the set speed.

Press the reset button, check the gas fan lead

cable, check the flue gas fan and replace the gas

fan.

26

Gas fan fault

The gas fan does not stop.

Press the reset button, check the gas fan lead

cable, check the flue gas fan and replace the gas

fan.

40

System pressure switch

fault

The system pressure switch has responded.

Check the system pressure switch.

Check the system pressure.

41

Flow monitoring

Flow temperature 1 > flow temperature 2 + 12 K ,

temperature change too great.

Vent the heating system, check the system

pressure.

Check heating circuit pump.

45

Fault sensor

Flow rate

Lead or sensor faulty or not connected.

Check the lead and replace the sensor, if required.

46

Fault DHW outlet

temperature

Lead or sensor faulty or not connected.

Check the lead and replace the sensor, if required.

52

Max. cylinder heating

time exceeded

The cylinder heating time takes longer than is set.

Check drawing rate, check DHW cylinder.

78

Manifold sensor faulty

The manifold sensor is outside its permitted range. Check manifold sensor, replace.

(The calculation of the set flow temperature

changes according to the flow sensor).

Summary of Contents for CGG-2-18

Page 64: ...64 3062347_0309 Notes ...