38

3062547_201802

Excess boiler water temperature

during cylinder heating

Parameters HG25

The excess temperature differential between the cylinder temperature and the boiler

water temperature during cylinder heating is selected with parameter HG25. The boiler

water temperature continues to be limited by the maximum boiler water temperature

(parameter HG22). This ensures that, even in spring and autumn, the boiler water

temperature is higher than the cylinder temperature, thereby ensuring short heating

times.

HG25

Factory setting: 10 K

Setting range: 0 to 40 K

10

Burner operating mode

Parameter HG28

Factory setting: 2

Setting range: 1 to 5

You can select any burner operating mode. Control unit is set at the factory for two-

stage burner operation.

Setting "1":

single stage burner operation, stage 1

Setting "2":

two-stage burner operation, stages 1 + 2

Setting "3":

Burner is single stage for cylinder heating

Burner is double stage for heating mode

Setting "4":

Burner is single stage for heating mode

Burner is double stage for cylinder heating

Setting "5":

Burner is double stage for heating mode, anti-cycling

according to the parameter HG09

Burner is double stage for cylinder heating. For cylinder

heating, the burner is locked for 4 min after every burner

shutdown.

HG28

2

Maximum boiler water temperature

TK-max.

Parameters HG22

Factory setting: 80 °C

Setting range: 50 to 90°C

The control unit is equipped with an electronic boiler temperature controller which has an

adjustable max. off temperature (max. boiler temperature). The burner is switched off if

this temperature is exceeded. The burner will restart when the boiler water temperature

has fallen by as much as the burner switching differential.

If the boiler water temperature exceeds 95 °C (possible effect of reheating), the boiler

circuit pump and cylinder primary pump (if installed) will also be started in "summer

mode". These pumps are stopped again when the boiler water temperature falls below

92 °C. This prevents the boiler overheating.

HG22

80

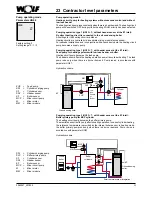

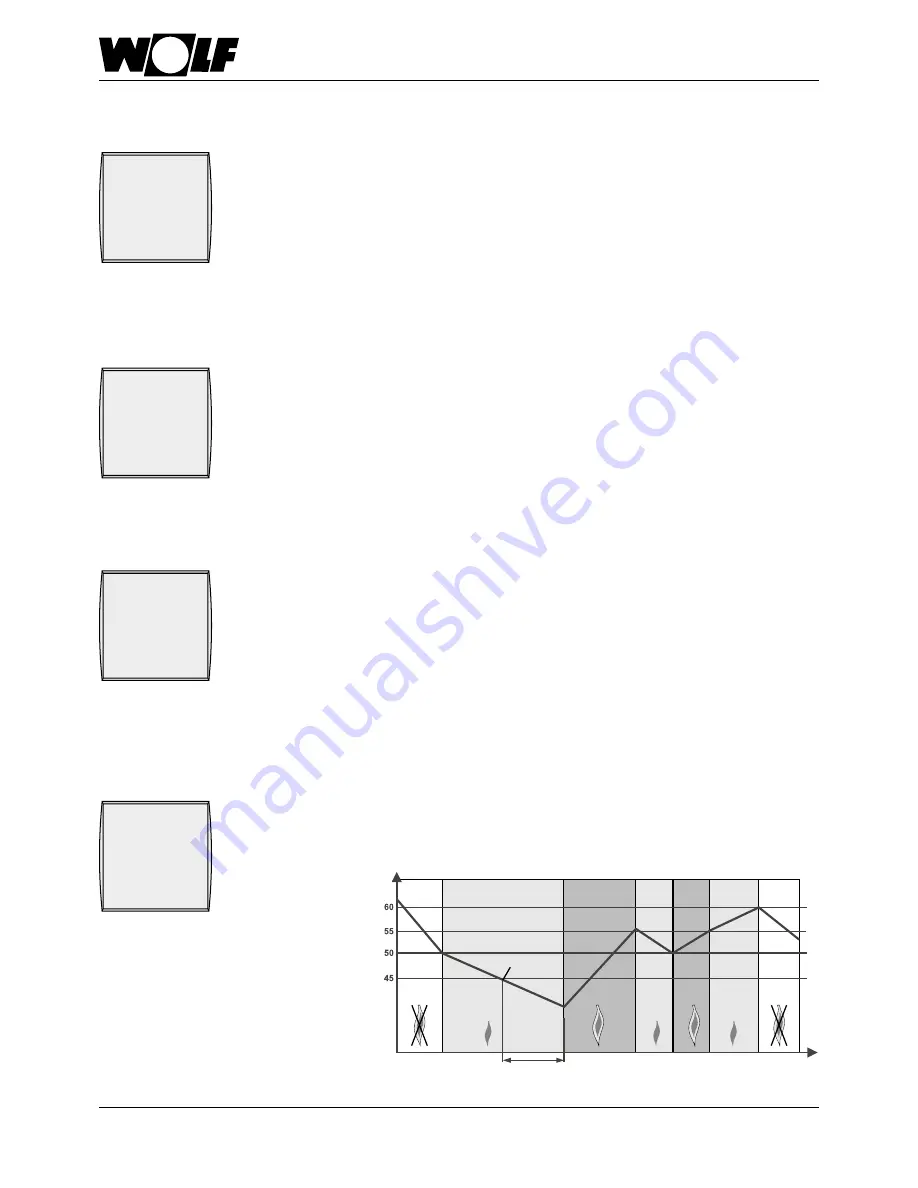

Blocking time burner stage 2

Parameter HG31

Factory setting: 10 min

Setting range: 0 to 40 min

10

Burner stage 2 is started when there is stage 2 demand and after the blocking period

has expired (factory setting 10 min.). It is stopped once a temperature of approx. 5 °C

above the set value has been reached. Once the stage 2 has been enabled, it will be

started as soon as the set temperature has been reached or is no longer achieved.

Enabling is removed when burner stage 1 is shut down.

During cylinder heating and emissions test mode, this parameter is disabled.

Time

Blocking period, factory

setting 10 min

Boiler

temperature °C

Burner

stage 1

Burner stage 1

Burner

OFF

Burner

stage 1

Burner stage 2

Burner

stage 2

Burner

OFF

Set val.

Demand

Stage 2

23 Contractor level parameters

HG 31

Summary of Contents for COB

Page 78: ...78 3062547_201802 43 Notes ...

Page 79: ...79 3062547_201802 43 Notes ...