40

3062547_201802

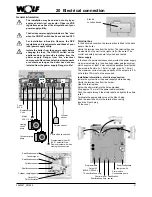

Heating circuit

The following types of connections shall be selected to ensure the heating water flow

rate through every condensing boiler is as even as possible:

1. For precise hydronic balancing, a line regulating valve can be fitted in the supply line

to every appliance.

2. Design the flow and return lines with the same length for the flow and return according

to the Tichelmann system, to ensure the pressure drop in every line is equally high.

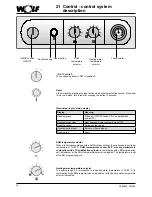

Low loss header

It must not be possible for the on-site heating circuit pumps or primary pumps to

influence the function of the condensing boilers. A low loss header should therefore be

installed upstream of the heating water circuit or DHW cylinder circuit. Furthermore,

ensure that the heating water flow rate through the condensing boilers is set lower

than that through the subsequent heating circuit. The flow rate should therefore be set

upstream of the low loss header via a line regulating valve or butterfly valve.

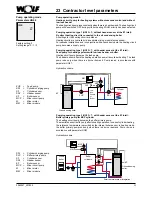

Hydraulic separation

Instead of the low loss header, a heat exchanger can be installed. If pipes are used

which are not impermeable to oxygen, this is a requirement in any case.

Directly heated DHW cylinder

A DHW cylinder is generally connected downstream of the system separation or via a

low loss header.

Cylinder heating is controlled via the cascade controller type KM, to which a cylinder

primary pump and the electronic cylinder sensor are connected.

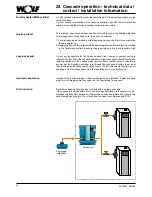

24 Cascade operation - technical data /

control / installation information

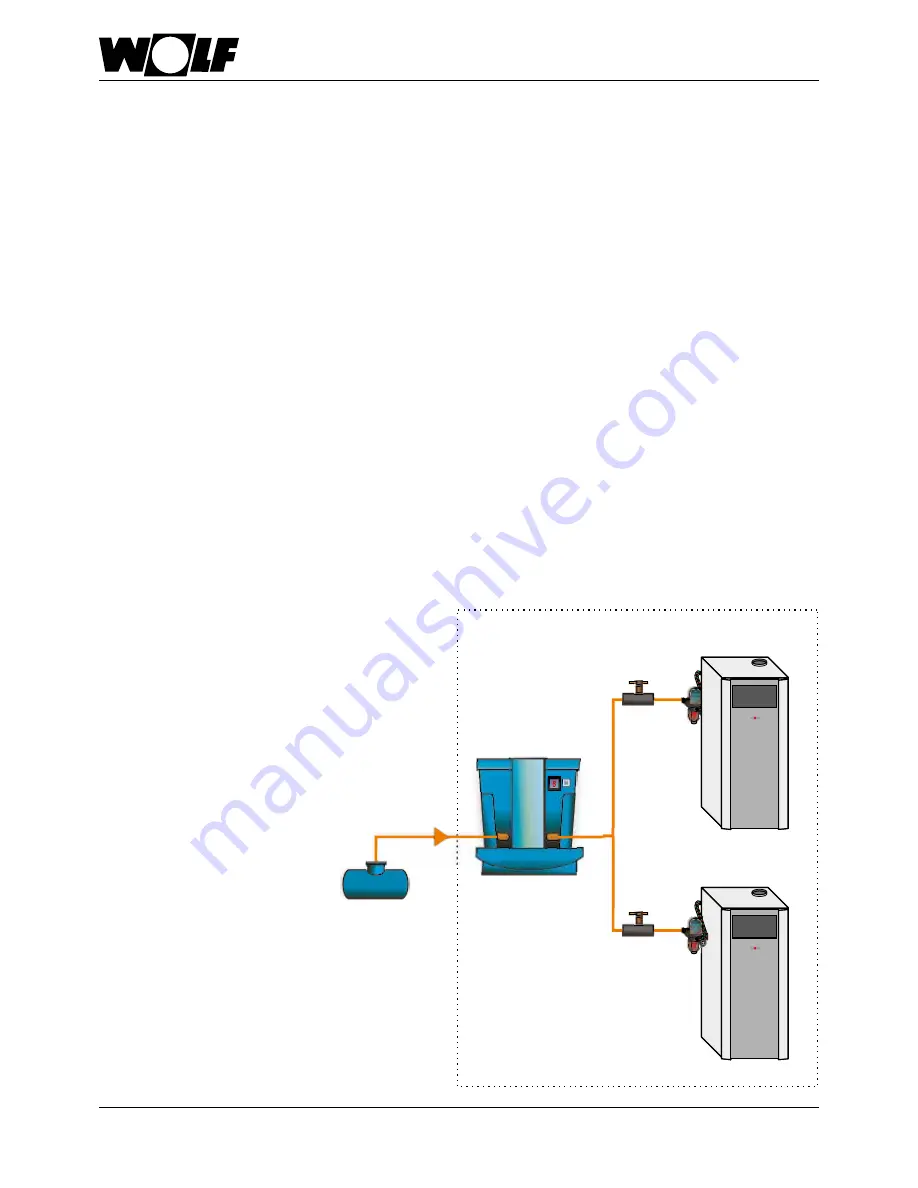

Oil connection

Each oil condensing boiler shall be provided with a suitable oil supply.

If the oil supply is only possible from one oil storage installation, this supply must be

arranged centrally via a suction unit The suction unit shall be installed as close to the

boiler cascade as possible. The oil lines shall be sized in accordance with TRÖl.

Oil storage

installation

Suction unit

Summary of Contents for COB

Page 78: ...78 3062547_201802 43 Notes ...

Page 79: ...79 3062547_201802 43 Notes ...