44

3062547_201802

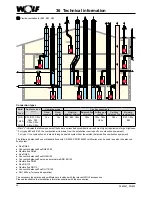

In the vertical part of the flue, a cleaning and inspection aperture is required immediately

above or below the flue diverter if the distance from the centre of the cleaning and

inspection aperture in the horizontal part of the flue to the vertical axis of the flue is

greater than 30 cm.

The distance can be up to 1 m if the inspection aperture in the horizontal part of the flue

is arranged on the front and if there are no diverters in the flue from this cleaning and

inspection aperture to the vertical part.

In the upper part of the flue arranged inside the building (< 5 m), a cleaning and

inspection aperture is required if cleaning or inspection cannot be carried out from the

roof.

Before commissioning the combustion system, have the safe usability of the flue

system confirmed by the local flue gas inspector [in Germany; check local regulations].

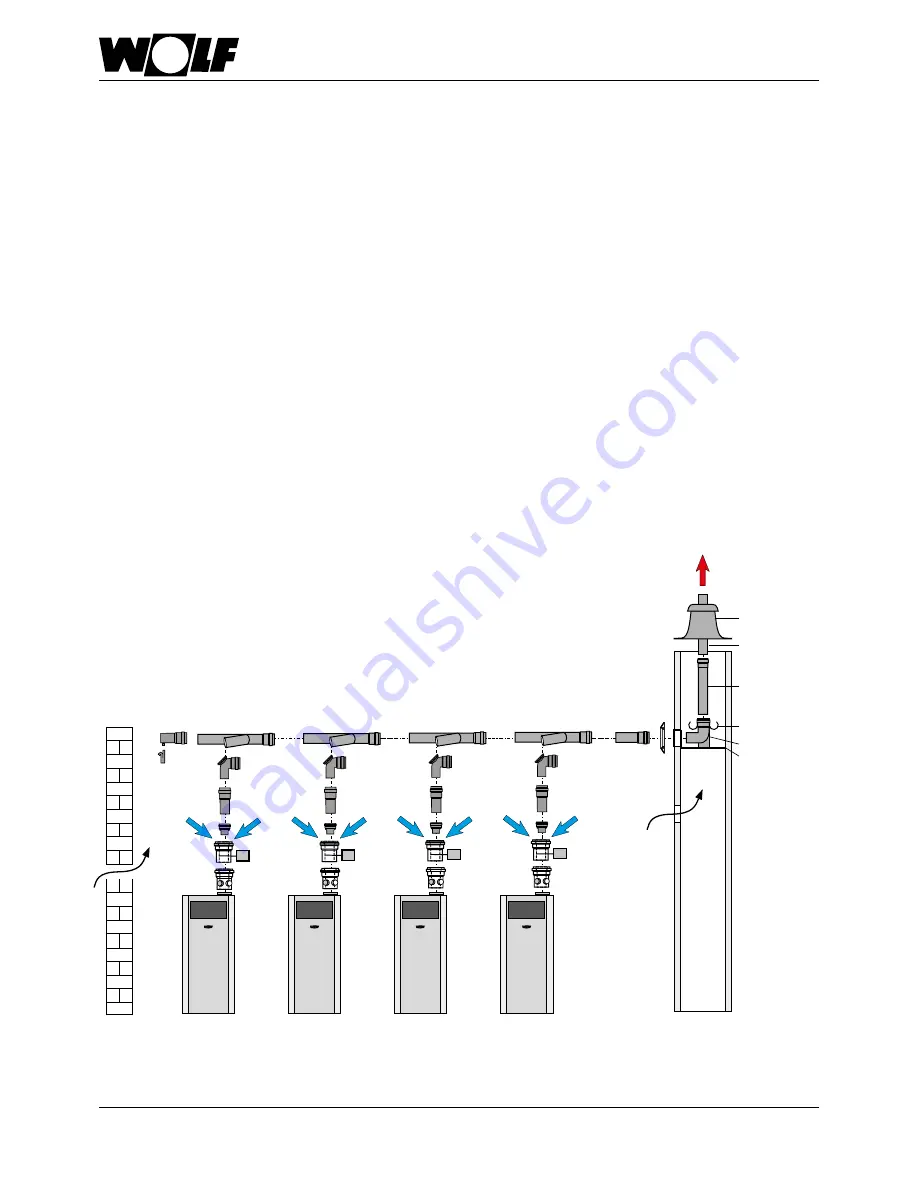

Installing the flue

26

16

23

24

25

26

27

33

37

37

37

37

38

32

26

35

34

2

32

26

35

34

2

32

26

35

34

2

32

26

35

34

2

36

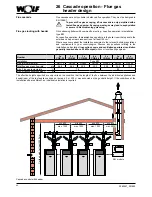

1 Oil condensing boiler

2 Connection adaptor with test nipple for

air and flue

gas (included in COB standard delivery)

16 Pipe collar

23 support rail

24 87° support bend

25 Spacer

26 PP pipe

27 Shaft cover

33 PP outlet

34 Check the Flue gas damper

35 Extension (where required)

36 Trap

37 PP header

38 End piece with inspection aperture and condensate

drain

Secondary

ventilation

Example of an open flue cascade design according to type B23

1

1

1

1

26 Cascade operation - Flue gas

header design

Summary of Contents for COB

Page 78: ...78 3062547_201802 43 Notes ...

Page 79: ...79 3062547_201802 43 Notes ...