62

3062547_201802

3

3

8

8

4

4

4

9

9

3

5

5

10

4

5

11

12

13

6

14

S

S

6

6

6

4

5

4

7

7

7

1

2

1

2

1

2

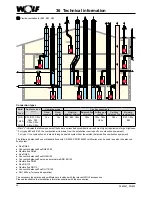

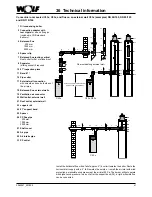

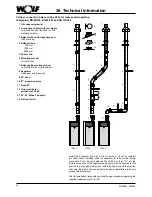

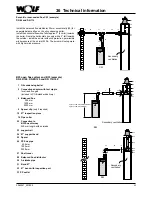

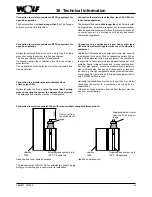

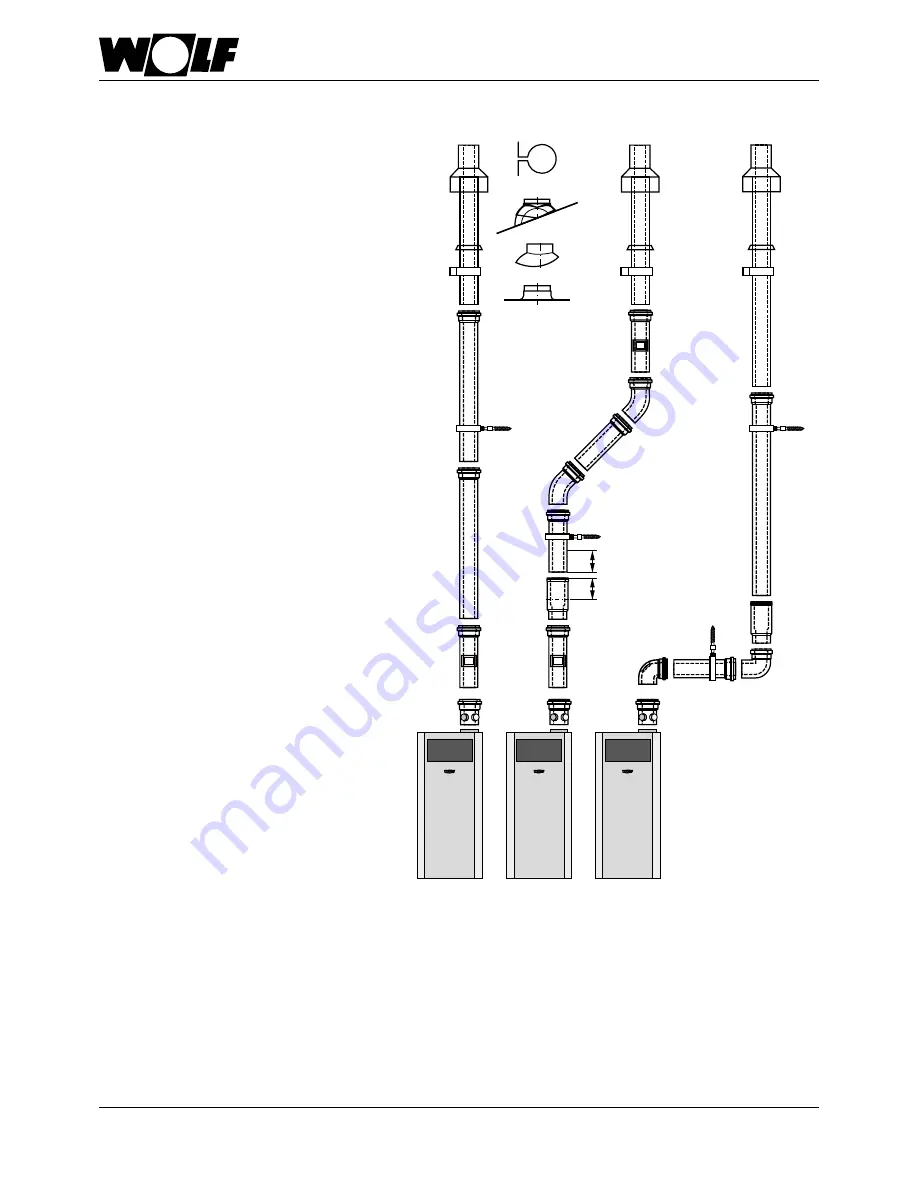

Vertical, concentric, balanced flue C33x for room sealed operation

(Examples) DN 60/100, DN 80/125 and DN 110/160

1 Oil condensing boiler

2 Connection adaptor with test nipple

for air and flue gas (included in COB

standard delivery)

3 Balanced flue with inspection port

(250 mm long)

4 Balanced flue

500 mm

1000 mm

2000 mm

5 Spacer clip

6 Mounting bracket

for roof outlet

7 Balanced flue routing vertical

(roof outlet) for flat or pitched roof

8 Separator

(sliding socket) if required

9 45° bend

10 87° inspection piece

11 Bend 87°

12 Universal tile for

pitched roof 25-45°

13 20°-50 "Klöber" adaptor °

14 Flat roof collar

Install the horizontal flue with a fall of approx. 3° (6 cm/m) towards

the boiler. When installing, slide the separator (8) fully into the female

connection. Push the next balanced flue (4) 50 mm (dim. "S") into the

female connection of the separator and ensure it is fully secured in this

position, e.g. with pipe clamps (5) or with a locking screw on the air side.

Lubricate the pipe ends and gaskets for easier installation (use only

grease without silicone).

Prior to installation, liaise with your local flue gas inspector regarding the

required inspection piece (3) (10).

C33 x

C33 x

C33 x

36 Technical information

Summary of Contents for COB

Page 78: ...78 3062547_201802 43 Notes ...

Page 79: ...79 3062547_201802 43 Notes ...