68

3062547_201802

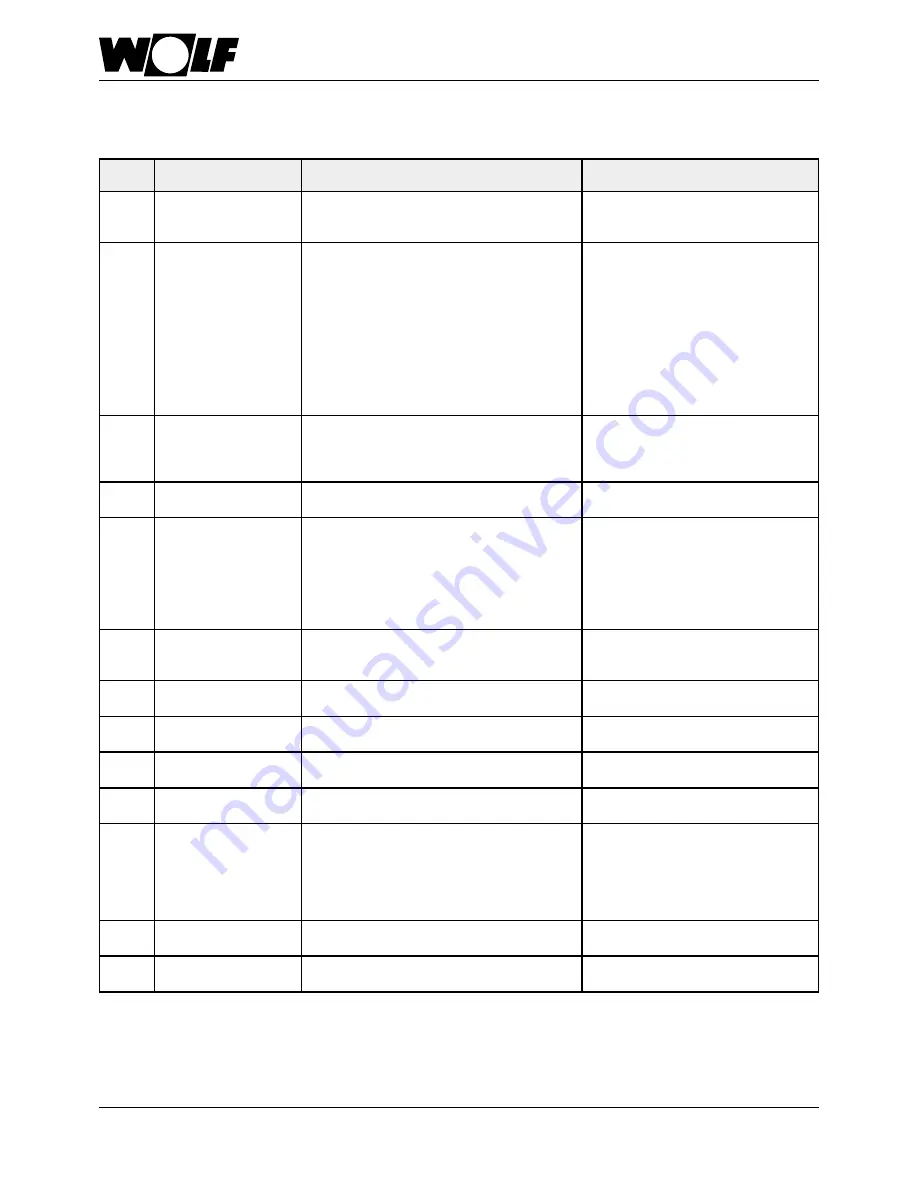

39 Troubleshooting

Any faults will be displayed as fault codes by Wolf controllers with eBUS capability. Cause and remedy may be allocated to these

faults using the following table . This table is designed to allow your local heating contractor to trace the fault more easily.

Fault

code

Fault

Cause

Remedy

1

HLSC excess temp.

The flow temperature has exceeded 110 °C

Test heating circuit pump,

vent system press reset button,

clean heat exchanger

4

None

flame established

No flame at burner start

Inspection window for flame monitor/mixer head

contaminated

Faulty flame monitor

Air in oil line

Negative pressure at oil pump too high,

max. 0.3 bar

Overpressure at oil pump too high, max. 0.5 bar

Boiler contaminated

Check oil line,

if necessary check fuel level,

check ignition electrode and ignition

transformer,

press reset

Check inspection window for flame

monitor/mixer head

Check flame monitor and lead

Check that the condensate can drain

off freely

Service required

5

Flame failure during

operation

Negative pressure on the oil pump is too high,

max. 0.3 bar flue gas return system (flue gas in

the supply air)

Boiler contaminated

Check CO

2

values,

check flame monitor and lead,

press reset, check flue system for

leaks, service required

6

Temperature limiter -

excess temperature

The flow has exceeded the limit of the

temperature limiter (100 °C)

Vent the system,

check the heating circuit pump

7

Flue gas sensor, excess

temperature

The flue gas temperature

has exceeded 120 °C

Clean the heat exchanger,

Check whether all displacement

devices are installed,

check the flow through the boiler

Check if flow and return are properly

connected

Press reset button.

8

Flue gas/supply air

damper does not

respond

Flue gas/ventilation air damper contact (E1)

fails to close or open when there is a demand

Check flue gas/ventilation air damper

and wiring

11

External light

recognition

A flame is recognised before the burner starts

Press reset

Check oil pump solenoid valve

12

Boiler sensor faulty

Faulty boiler sensor or lead

Check sensor

and lead

14

Faulty cylinder sensor

SF

Faulty cylinder sensor or lead

Check sensor

and lead

15

Outside temperature

sensor faulty

Faulty outside temperature sensor or lead

Check sensor and lead

25

Fan fault

The fan does not reach the set speed

Boiler contaminated

Check supply to the fan

Check fan

Check that the condensate can drain

off freely

Check balanced flue system press reset

Service required

26

Fan fault

The fan does not stop

Check power cable to fan

Check fan Press reset

27

Faulty stratification

sensor

Faulty stratification cylinder sensor or lead

Check sensor and lead

Summary of Contents for COB

Page 78: ...78 3062547_201802 43 Notes ...

Page 79: ...79 3062547_201802 43 Notes ...