46

3063772_201507

25. Parameter description

Important information:

In these schematic diagrams, shut-off valves, air vent valves and safety equipment are not fully represented. These should be

provided in compliance with the applicable standards and regulations for each individual system.

Hydraulic and electrical details can be found in the Hydraulic System Solutions technical guide.

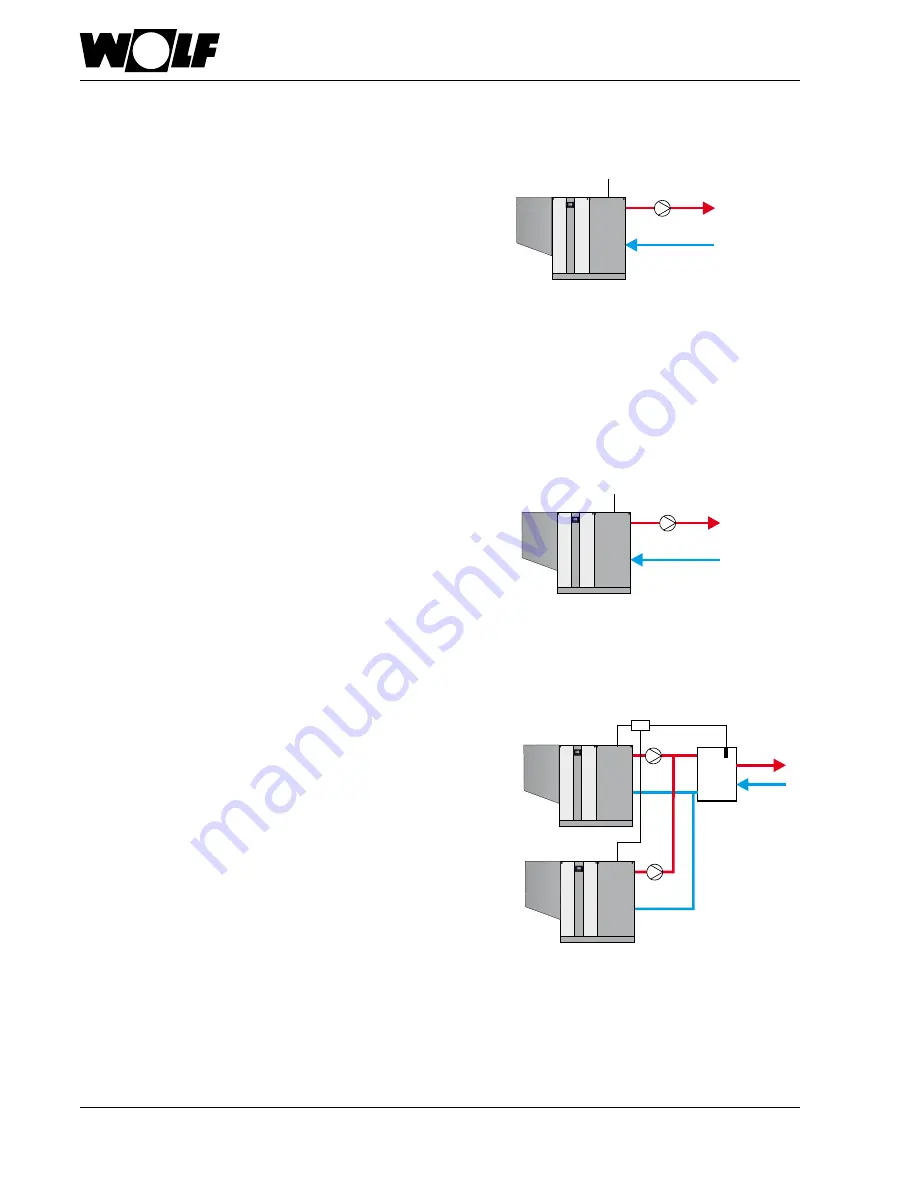

System configuration 51

BMS burner output

E2

BMS%

ZHP

Burner is activated subject to demand from the external controller

•

Feed/heating circuit pump (ZHP)

activated as feed pump from 2 V upwards

•

No temperature control

•

Input E2:

Control 0-10 V by external controller

0-2 V burner OFF,

2-10 V burner output min. to max. within the programmed limits

(HG02 and HG04)

•

Automatic output reduction when approaching TK

max

(HG22) is

activated. Deactivation on reaching TK

max

Note:

If the pressure drop of the boiler incl. the pipework is

> 700 mbar, a low loss header must be installed.

System configuration 52

BMS set boiler temperature

ZHP

E2

BMS°C

•

Burner is activated subject to demand from the boiler

thermostat

•

Feed/heating circuit pump (ZHP)

activated as feed pump from 2 V upwards

•

Boiler thermostat

•

Input E2:

Control by external controller with 0-10 V

0-2 V burner OFF

2-10 V set boiler temperature TK

min

(HG21) - TK

max

(HG22)

Note:

If the pressure drop of the boiler incl. the pipework is

> 700 mbar, a low loss header must be installed.

System configuration 60

Cascade for multi boiler systems (setting automatic when

cascade module is connected)

•

Burner is activated subject to demand from cascade module

via eBUS (0-100 % burner output; min. to max. within the

programmed limits) (HG02 and HG04)

•

Feed/heating circuit pump (ZHP) activated as feed pump

•

Header temperature control via cascade module

•

Input E2: not assigned

•

Automatic output reduction when approaching TK

max

(HG22)

is activated. Deactivation on reaching TK

max

• A low loss header or plate heat exchanger can be used as

system separation.

ZHP

SAF

eBUS

KM

eBUS

ZHP