13

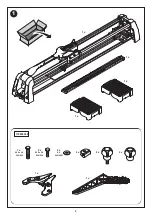

SCOPE OF SUPPLY

Take the tile cutter TC 670 Project out of the cardboard box and check, whether the delivery is complete, i.e. whether all parts shown in the

illustration have been delivered (Fig. 1).

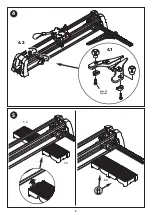

ASSEMBLY/INSTALLATION

First of all, put the cutting unit in the position as illustrated. Then remove the two supports from the tile cutter (Fig. 2).

Now install the serial or angle guide (Fig. 3). Following that, install the diagonal guide loosely, shift it onto the guide and tighten

both turning handles firmly (Fig. 4). The two supports can now be hooked in, depending on the actual application (Fig. 5).

WORKING INSTRUCTIONS

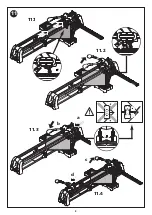

Parallel cuts (90°)

Move the cutting unit with the handle immediately next to the housing. Make sure that the breaking rod can always move freely above

the two sponge rubber strips, so as to avoid damaging them (Fig. 6). Now hook up the supports.

Setting the thickness of the material and the cutting width: First measure the thickness of the tile and set the adjusting lever (steps between

4 and 12 mm) at the cutting unit as shown in the table. Now put the tile up to the edge guide into the appliance. You can either set the cutting

width ranging between 50 and 300 mm directly via the angle guide (the detailed illustration shows an example of 160 mm) or mark the cutting

width with a suitable pencil on the tile (Fig. 7). Make sure that all three handle bolts at the ruler are properly tightened.

Scribing the tile surface: Put the lever in the “min” position. Now put the cutting wheel onto the tile and shift the cutting unit into its end

position / to the edge guide by using the handle. PLEASE NOTE: Should the pressure prove to be insufficient when scribing the tile with

the cutting wheel, the lever will have to be changed into its “maximum” position. The adjusting lever may also be set into the next

lower step “4 - 12 mm”, if necessary. Always make a trial cut first (Fig. 8).

Breaking the tile: Turn the handle in the direction of the arrow right up to the top. In doing so, the breaking rod will automatically turn

vertically towards the tile. Following that, you press the handle down and break the tile. The breaking rod must be positioned close to the

front edge of the tile, where a breaking cone has been integrated into the base plate to ease the breaking process. The tile will break along

the scribed line (Fig. 9).

Diagonal cuts (45°), square tiles

Install the angle guide as shown in the illustration. Align the tile with a corner in the V-groove at the appliance’s guide block.

Move the diagonal guide closely to the tile, until the V-groove hits the corner of the tile. Now arrest both handle bolts. Shift the angle guide

towards the tile until it hits it and tighten the handle bolt firmly (Fig. 10). Now set the thickness of the material and the scribing depth

(Fig. 7 & 8). First scribe the tile only. Before breaking it subsequently shift the cutting unit slightly backwards, so that the breaking rod comes

to rest completely on the tile. The tile will now break exactly along the scribed line (Fig. 11).

Transport

When taking the appliance somewhere else, shift the cutting unit into its end position as shown in the illustration. Then arrest both supports,

as-semble the diagonal and angle guide as shown in the illustration and carry the tile cutter

with both hands in its horizontal position (Fig. 12).

MAINTENANCE/SERVICE

• Inspect the tile cutter each time before using it.

• Remove dust and residues from the guide rails each time after using the tile cutter.

• Wipe off contaminants with a wet, soft cloth. Do not use any cleaning agents or solvents.

• Lubricate the guide rails of the TC 670 Project regularly, basically each time before using it.

• Keep the safety and all other instructions for future reference in a safe place.

ENVIRONMENTAL PROTECTION

Do observe all applicable local disposal regulations, when disposing of the tile cutter TC 670 Project.

Warranty

Dear hobbyist!

You have purchased a high-quality wolfcraft

®

appliance, which we know you will enjoy using. wolfcraft

®

appliances are built to high technical

standards, and undergo intensive development and test phases before leaving the factory. Constant controls and regular tests during

their manufacture, ensure a high quality standard. Sound technical developments, and reliable quality controls warrant for the right choice

of appliance.

We provide a warranty of 5 years from the day of purchase on the wolfcraft

®

product you acquired, provided it is exclusively used for DIY

purposes. The warranty only covers damage to the item purchased, and only such damage that can be attributed to faulty material und poor

workmanship. The warranty does not cover defects and damage that must be attributed to improper use or insufficient maintenance.

Nor does the warranty cover the usual wear and tear as well as defects and damage, of which the customer has been aware when purchasing

the equipment.

Warranty claims can only be asserted by producing the invoice or the till receipt.

The warranty granted by wolfcraft

®

does not in any way restrict your statutory consumer rights (i.e. contract performance, withdrawal from

the contract, price reduction, claims for damages or reimbursement of expenses).

t