7. There are two holes in the metal rim of the LED head. Use the metal rim as a template and mark the two

holes locations on the light assembly housing and drill to size using an 1/8” drill.

8. Clean the interior of light assembly and lens of any dust or filings, which may have developed during cutting

the hole.

9. Re-install the OEM factory light assembly and reflector.

10. Place the rubber gasket around the LED head

and install the head into the one (1) hole and

secure using the self-tapping screws

(provided).

11. Repeat the same installation procedure for

the remaining LED heads.

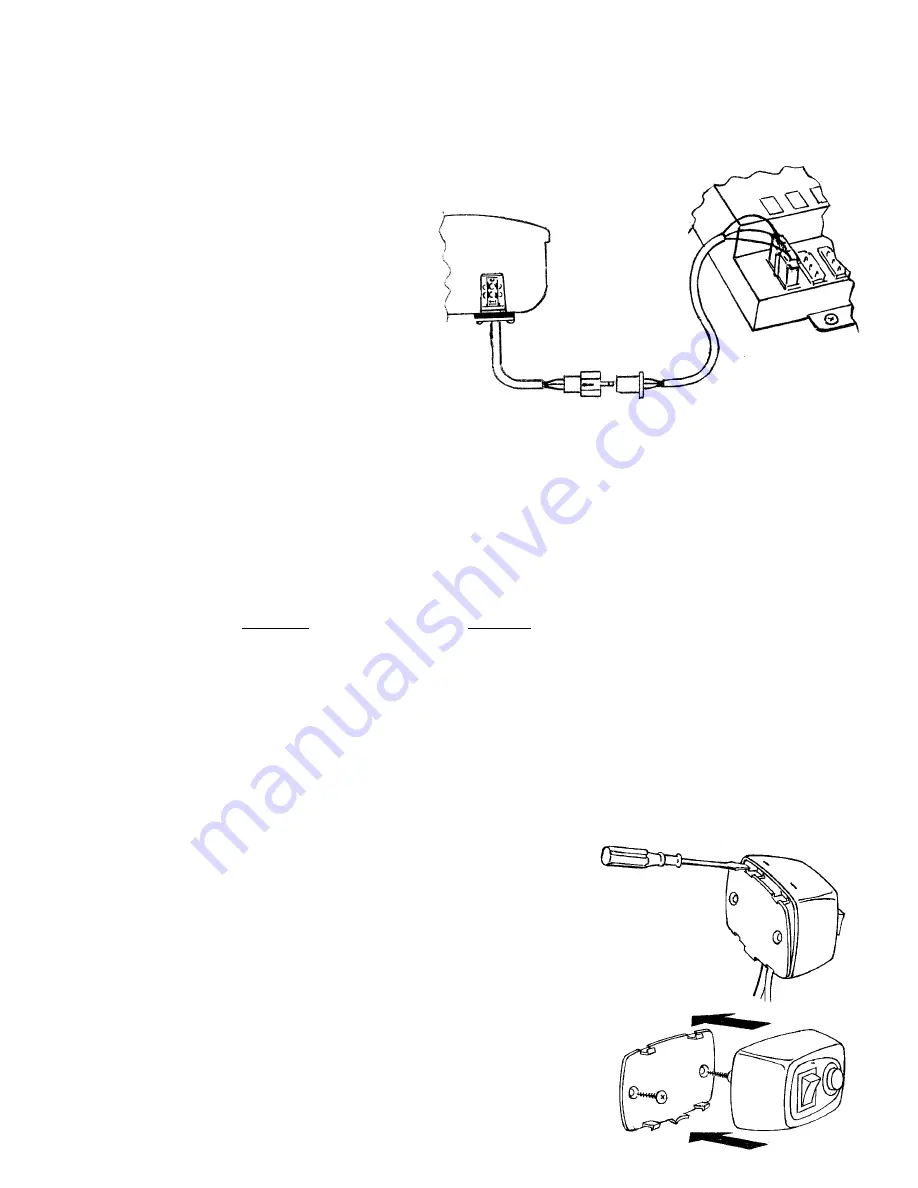

WIRING LED HEADS Fig. C

IMPORTANT: To prevent damage to the power

supply, DO NOT connect any power source until

all of the LED heads are completely wired to the

power supply. All 8504 models come with four (4)

cables that are used to connect the LED heads to

the power supply. Each cable has two female plugs, one at each end. The plugs are different and will only

connect to its mate, either the LED head, or power supply.

12. Two of the cables are 3 meters / 9.8 ft. in length and should be used to connect the LED heads installed in

the front light assemblies to the power supply position L1 & L2.

13. Two of the cables are 5 meters / 16.4 ft. in length and should be used to connect the LED heads installed

in the rear light assemblies to the power supply position L3 & L4.

NOTE: If you need to lengthen the rear cables, see chart below for proper wire gauge.

16-30 ft.

31-50 ft.

Use 18 Gauge or heavier

Use 16 Gauge or heavier

MOUNTING SWITCH CONTROL PANEL

Using double face tape or screws

TAPE METHOD

14. Select a mounting location for the control panel that is easy to reach. IMPORTANT: Be sure that the switch

control panel or its wires will not interfere with air bags or the driver’s vision.

15. Using the double-sided foam adhesive tape provided, mount the control panel to selected location. Make

sure that mounting surface is free from dust, wax etc. A clean surface is necessary so that double-sided

tape will hold properly.

IMPORTANT: THE ADHESIVE HOLDING POWER BECOMES

MAXIMUM IN ABOUT 24 HOURS. LIMIT MOVING OR PUTTING

PRESSURE ONTO THE KEYBOARD UNTIL THEN.

SCREW METHOD Fig. D & E

16. Remove the control panel’s backing plate using a flat tip screwdriver.

17.Using the backing plate as a template, mark the two hole locations

onto the mounting surface where the switch panel will be mounted and

drill to size using a 3/16” drill. IMPORTANT: The installer must

carefully inspect both sides of the mounting location before drilling any

holes to ensure that there are no components, wires and or any

vehicle part that could be damaged by drilling.

18. Position the backing plate on the mounting surface and secure using

the two sheet metal screws provided that have the countersunk head.

19. The control panel is carefully pushed onto the backing plate.

Fig. C

Fig. D

Fig. E

HOLE SIZE

3/16”