. Following the instructions in this manual

will provide a longer and safer service life for your air compressor.

CAUSE SERIOUS INJURY OR LOSS OF LIFE.

TO REDUCE THE RISK OF FIRE OR EXPLOSION. NEVER SPRAY FLAMMABLE LIQUIDS IN

A CONFINED AREA

It is normal for the motor and pressure switch to produce sparks

CAUSE SERIOUS INJURY OR LOSS OF LIFE.

Summary of Contents for W3D1/24

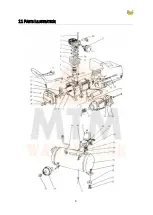

Page 10: ...9 11 PARTS ILLUSTRATION...