6

3 .

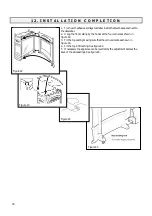

G E N E R A L I N S T A L L A T I O N R E Q U I R E M E N T S

3.1

The installation must be in accordance with these instructions.

For the user’s protection, in the United Kingdom it is the law that all gas appliances are

installed by competent persons in accordance with the current edition of the Gas Safety

(Installation and Use) Regulations. Failure to install the appliance correctly could lead to

prosecution. The Council for the Registration of Gas Installers (CORGI) requires its

members to work to recognised standards.

In the United Kingdom the installation must also be in accordance with:

a)

All the relevant parts of local regulations.

b)

The current edition of the Building Regulations issued by the Department of the

Environment and the Welsh Office or the Building Standards (Scotland) Regulations

issued by the Scottish Development Department.

c)

All relevant codes of practice.

d)

The relevant parts of the current editions of the following British Standards:-

BS 715

BS 5440 Part 1

BS5440 Part 2

BS 5482 Part 1

BS 5871 Part 1

BS 6461 Part 1

BS 6891

In the Republic of Ireland the installation must also conform to the relevant parts of:

a)

The current editions of:-

IS 813

b)

All relevant national and local rules in force.

3.2

Before installation, ensure that the local distribution conditions (identification

of the type of gas and pressure) and the adjustment of the appliance are compatible.

3.3

This appliance is designed for use with a Selkirk IL twin-wall 100mm (4in)

residential gas vent system with a minimum effective height of 10 ft (3.05m).

3.4

This appliance must not be installed in any room which contains a bath or

shower or where steam is regularly present.

3.5

An extractor fan may only be used in the same room as this appliance, or in any

area from which ventilation for the appliance is taken, if it does not affect the safe

performance of the appliance. Note the spillage test requirements detailed further on in

this manual. If the fan is likely to affect the appliance, the appliance must not be installed

unless the fan is permanently disconnected.

3.6

I

n the United Kingdom (GB)

no special ventilation bricks or vents are required

in the room for this appliance

.

In the Republic of Ireland (I.E.), permanent ventilation must comply with the regulations

currently in force.

3.7

Note that soft wall coverings (e.g. embossed vinyl, etc.) are easily affected by heat.

They may scorch or become discoloured when close to a heating appliance. Please bear

this in mind when installing.

3.8

Minimum clearances to combustible surfaces and for servicing access are shown

in figure 1.

3.9

Propane gas appliances must not be installed in a cellar, basement or any room,

which is built entirely below ground level (See BS5482 Part 1).

3.10

The top castings, front castings above the access door and the glass window are

working surfaces. They become hot in use and should not be touched until the stove is

switched off and allowed to cool.