5

CLEANFIRE OUTDOOR FURNACE • OWNER'S MANUAL

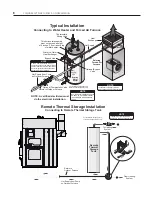

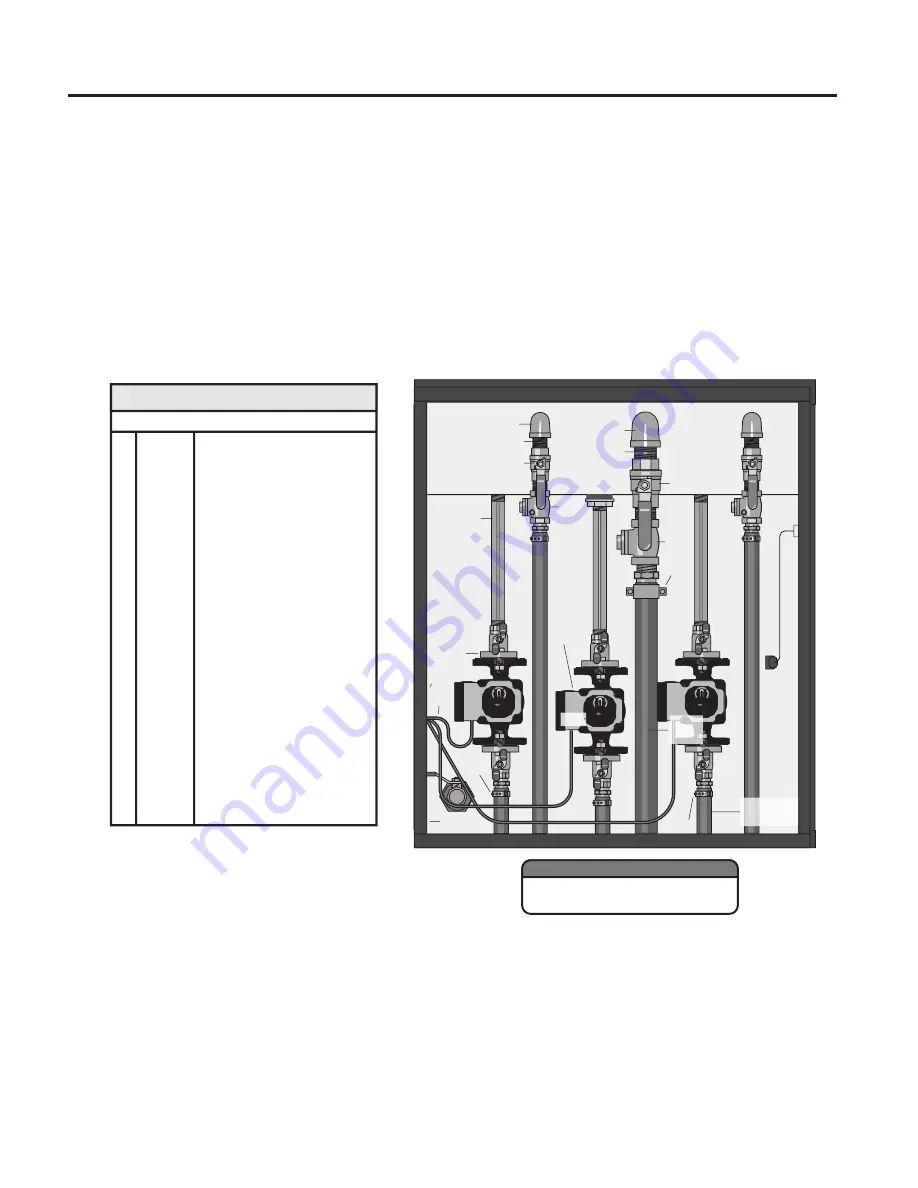

Access to Ports on Outdoor Furnace

Ports are provided that allow mounting circulation pumps on the outdoor

furnace. Refer to the illustrations in this section for proper supply and return

line and pump installations for your model.

NOTE: The Installation Guide provides more information on pump selection. For even

more detailed information, see the Hydronic Component Selection Guide (p/n 2482),

available from your WoodMaster dealer.

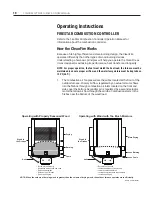

Qty p/n Description

3 5800033 0015e3 Pump

2

118

Close Nipple, 3/4"

2

224

Isolation Flange Kits, 3/4"

2

198

Ball Valve, 3/4"

2

296

Swing Check Valve, 3/4"

2

274

90° Street Elbow, 3/4"

4

5926

Crimp Ring, 1"

Stainless Steel Clamp

3 - Pump Parts List*

3

556

Power Supply Cord, 32"

1

582

6 Outlet Converter

4

1330

MPT to PEX, 3/4" x 1"

1 5000015 Nipple, 1-1/4" x 2-1/2

3

536

Nipple, 3/4" x 7"

1

6593

Grounding Rod Kit

2

409

Close Nipple, 1-1/4"

1

411

90° Street Elbow, 1-1/4"

2

5643

Brass Clamp, 1-1/4"

1

410

Ball Valve, 1-1/4"

1

225

Isolation Flange Kits, 1-1/4"

1

5871

Swing Check Valve, 1-1/4"

*Parts and accessories sold separately.

Pump size may vary.

NOTE

Grounding Rod Kit (p/n 6593) must

be installed with every furnace.

For illustration purposes only.

118

5800033

198

536

225

296

409

410

5871

411

556

6593

582

274

1330

5643

5926

1-1/4"

PEX

1" Central

PEX

224

CleanFire 700 Model – 3-Pump Configuration