35

CleanFire Owners Manual

2016

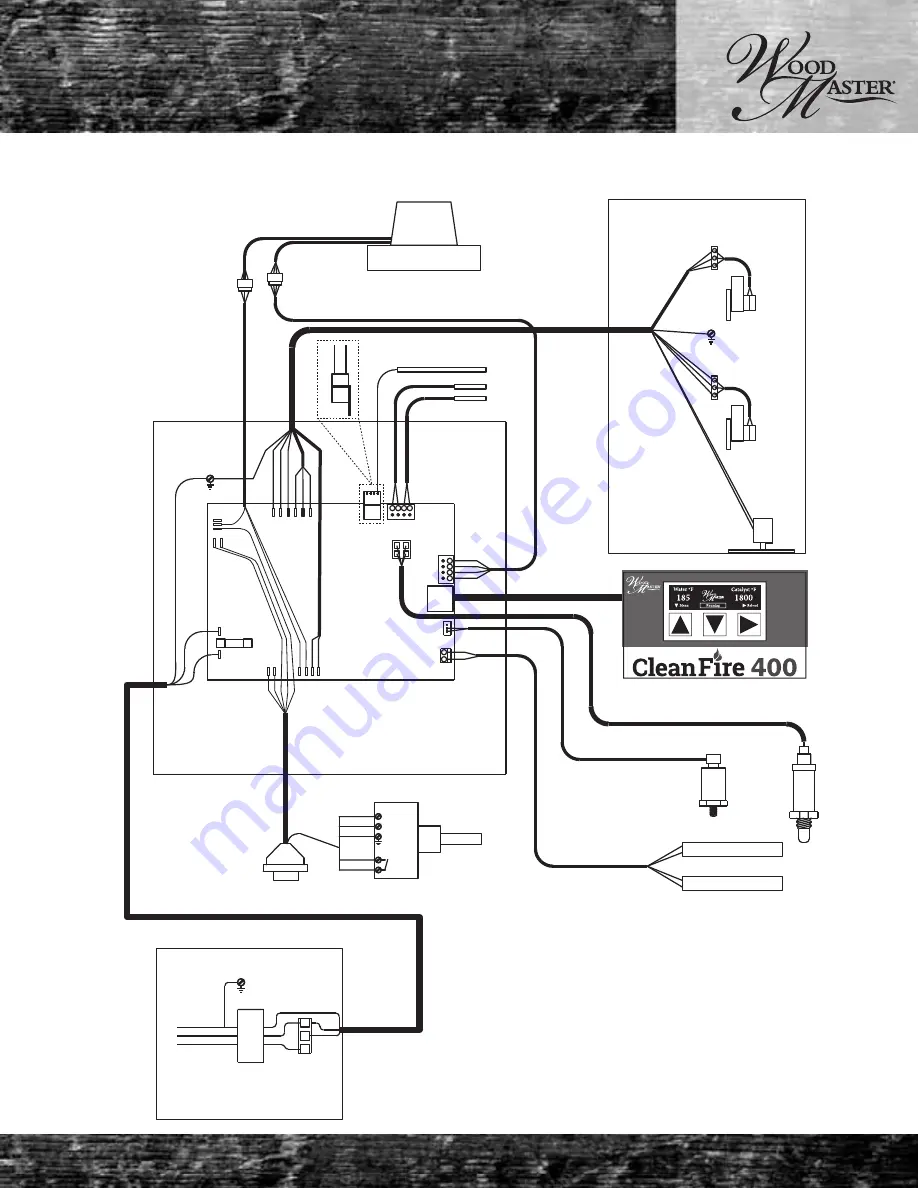

Wiring

Grn

Grn

Br

n

Br

n

Wh

t

Blk Gr

n

Blk Blu

Wht

Blk

AC OUT 3

Wh

t

Red Blk Wh

t

Red Blk

2 Pos

Outlet

Grn

Wht

Blk

120 VAC 60Hz

Service IN

(14-2 w/ground)

Wht

CB 10A

Reset

2

3

1

Blk

Blk

4X4 Junction

Grn

Wht

10X10 Junction

Grn

Wht

Blk

5A

Master

Solenoid

Damper 0

Primary

L1

N

Earth

Inducer Fan

Secondary

Primary

Damper 1

Secondary

LED Light

LED Light

Air Box

-

+

0-50

PSI

OLED Front Display

3210

TC

Wht

Catalyst Thermocouple

Return RTD

Supply RTD

Red

Yel

Blu

Red

Blk

O2

1 0

RTD

Grn

Gr

y

Gr

y

200ºF

Snap Disc

Low

Water

Cutoff

N

H

Wht

Blk

Grn

Brn

Brn

Brn

Brn

8/15/16

Red Ye

l

3210

Side

View

Fr

on

t

TC

All wiring should be done by qualified persons.