Maintenance

RPM Adjustments

Maintenance

3/10/20

3-4

3

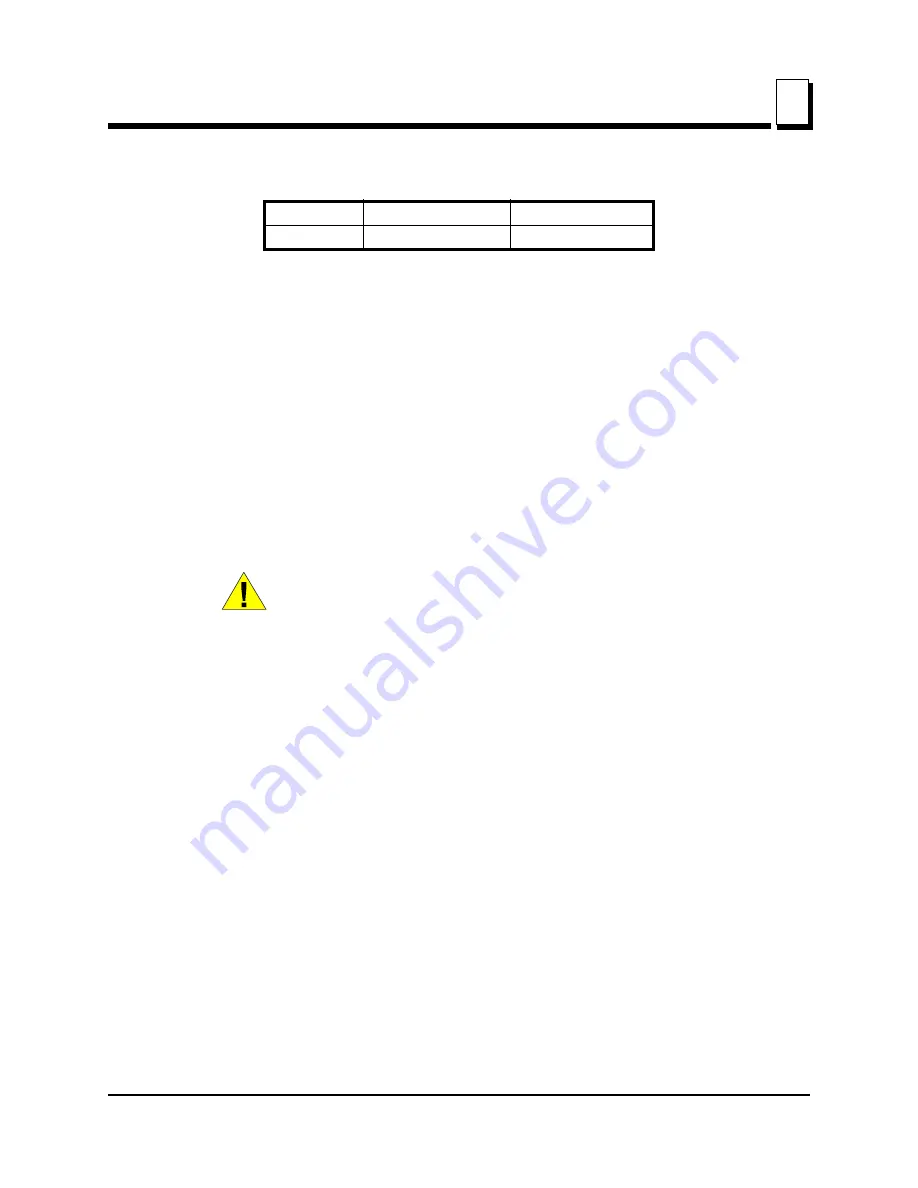

See Table 3-1.

Before checking the RPM, make sure belt and brake strap tensions are correct (See Saw-

mill Maintenance). Also check oil, fuel, and coolant levels.

D35 Tier4 Engine Only:

Check the Manufacturer’s Manual to see if the RPM adjustment

is necessary.

D35 Tier2 Engine Only:

See below for RPM adjustment.

Make sure the throttle solenoid linkage is adjusted properly. With the clutch disengaged,

the throttle linkage should rest against the idle adjustment screw. With the clutch

engaged, the linkage should rest against the high-end adjustment screw and leave 0” to

1/32” of play in the linkage.

CAUTION!

Failure to properly adjust the throttle solenoid linkage may

cause damage to the solenoid.

1.

Disengage the clutch and loosen the solenoid mounting bolts to adjust the throttle sole-

noid linkage.

2.

Adjust the solenoid as far to the right as possible and retighten the mounting bolts.

3.

Engage the clutch and recheck the amount of play in the linkage.

If there is more that 1/32” of play in the linkage with the clutch engaged, disengage the

clutch and turn the linkage turnbuckle.

4.

Repeat adjustments to achieve 0”-1/32” of play in the linkage with the clutch engaged.

Engine

High End RPM

Low End RPM

D35

3000

1500

TABLE 3-1